Many times the woodworkers( amateurs or not ) are searching for ways to make their carpentry projects stronger , more protected in order to last longer and with the less possible problems . That’s why they experiment with several ways , several physical elements , several chemical elements and whatever else .

They use all the technology they can and all the range of the elements they can . Many carpenters like and prefer the natural ways and many are not . The most common way to protect and make your wood stronger using chemicals are with impregnation .

You’ll need some money for this , but it’s very effective .

I’ve written the entire process in HERE , if you like to remember it .

Of course there are many other ways and one very efective to make your wood’s mass more stronger with zero chemicals , is the thermical modification . In this method we use zero chemicals at all .

You’ll need some money for this , because it’s made into pressure ovens – kilns , but it’s way less expensive than the chemical impregnation methods , because we use zero chemicals , salts , et.c .

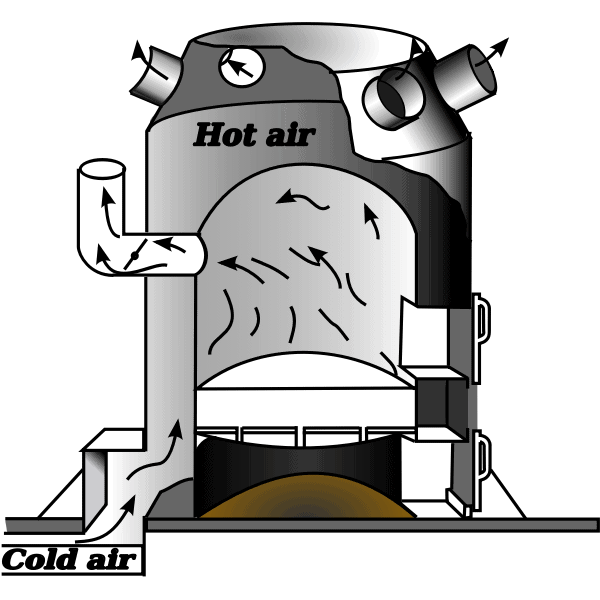

The thermical modification uses only the heat and moisture to make wood better . It’s a four stage method and here it is :

1) Hydro-thermolysis .

In here the wood’s mass is heated inside ovens between the 160o -170o celcius with the presence of moisture and with higher pressure the normal atmospheric .

In this way we transform the wood’s lignin into aldehydes , while the cellulose stays unharmed !! That’s why we have undamaged the mechanical properties of wood .

2) Drying .

In this stage , we dry our wood in kilns ( kiln drying ) seting the moisture to 8% . In this way we reduse the errors of wood . Crackings , strech marks , et.c .

See in HERE a post for the properties and errors of wood .

3) Polymerization .

In here we dry our wood around to 180o celcius , without moisture at all . Completely dry circumstances . Chemical reactions(polymerization) are made in here in the cells of the wood , that they give it great stability and way higher resistance .

The color of the wood is changing , becoming brown or more brown .

4) Final Moisture Conditioning .

In here our very low moisture wood ( around to 1%) , gets its appropriate moisure back ( re-hydrate ) till the 8% – 12% and it’s ready for use .

What are the Benefits of this process ?

1) We take better , more stable and general more strong wood , concerning the moisture and its biological properties .

2) We have zero chemicals , zero toxicity . It’s completely natural process , using only heat and moisture conditions .

3) This process needs a few energy and it isn’t very energy consuming .

4) It’s very eco friendly , of course .

5) We upgrade the properties of the more cheap and “common” wood( pine , spruce , et.c ) , with easiness , without harming the environment and our health .

6) We stabilize more the dimensions of our wood and make it more strong and stable generally .

7) We have the same mechanical properties – resistance and don’t “damage” the wood .

8) We make our wood more resistant to time and weather conditions .

9) The wood needs less maintenance from us , during time . If you like to see the eco friendly ways( oils & waxes only ) to protect your wood , see it in HERE .

10) It’s a very easy method to apply .

11) This thermical process – modification makes wood more stronger , with better biological – hydroscopic properties , more resistant and stronger . This means you can use more thin wooden boards , logs , et.c for decorative purposes , without losing any strength advantage .

You can also use less expensive wood , to do the same job and all this as you can imagine saves you money , without losing the quality you want for your final result .

12) Less maintenance means also more money savings for you , concerning the purchase of the protecting materials for your carptentry craft . In the long run you’ll save a lot of money .

If you want to see a complete maintenance list to protect your wood plans , read in HERE .

13 ) You can use this modified timber to replace tropical and more expensive wood , for your outdoor woodworking crafts and especially if you create underwater projects . Outside fences , public constructions near lakes , aquariums , et.c .

See some of my favorite oils – waxes to buy and preserve your wood very eco-friendly , in HERE .

What Woodworking Projects can i create using this Thermical Modified wood ?

This thermical modification creates very strong wood for the outdoor activities for sure , but not only . You can use this kind of wood for your indoor creations if you want the maximum of strength and performance , without spending a fortune .

You can create woodworking power tool boxes and other tool parts , strong shelves , outdoor fences , aquariums , public seats , shelters , in decking and boats in general , in all the sea or the near the sea activities , in pools replacing the marine plywood with great results .

This wood can be used by public agencies , saving a lot of money from their budget . You can create very nice wooden furniture for indoors and especially the outdoors .

As you see the woodworking “planet” always moves and evolutes , trying to discover more ways and better , eco -friendly ways to use wood .

Keep woodworking and gaining happiness .