I know that many , like their woodworking plans to be finished and treated as raw as they can possible can and of course this “old school” approach is very respected , because it worked for so many time .

Of course there are more ways to treat your wood , but only one of them gives to wood almost perfect or perfect protection for its entire mass , not only the surface .

The protection of your woodworking projects with impregnation is a must method for the ones who want more protection , for their Woodworking plans .

Personally i don’t like much to paint my wood or use chemicals to protect it , but sometimes you can’t do otherwise when you’re dealing with green elements as wood is .

I like the smell and the touch of the wood in its primary form , protecting them only with a finishing oil (linseed mostly) , but in some of my projects , i’ve used impregnated wood .

“Old times” wood protection methods , you should Avoid .

Many “old school” carpenters used petroleum for their woodworking projects mostly because they didn’t know the Shu Shougi Ban technic . and the petroleum was a cheap solution .

The petroleum protects the wood in a very high level from bugs and wood’s fungi , but it’s chemical , highly toxic and i don’t suggest you to use it , in no way .

I don’t also suggest you to use tar or any other toxic material , in order to protect your wood from its enemies .

The modern chemistry has invented so many eco friendly materials to use for protection and your wood’s finishing , that the “old days” techniques ( many of them toxic) are “antiquated” already .

Is impregnated wood Toxic ?

Yes it’s a toxic process , because we don’t use totally natural elements to protect wood and we use chemical salts and other kind of chemicals , till we have a fully coverage of the entire mass of wood .

Always remember that a material that isn’t 100% natural and approved that is harmless for the human health , should considered toxic and can damage health in a wide range of posibilities .

Even the smallest trace of chemicals inside a totally natural element , it makes it automatically not totally natural and it hides dangers , till the professionals and authorities will say the opposite .

I avoid toxicity in every case i can and i suggest you to do the same .

Why impregnate wood ?

The impregnation process has the colossal advantage that the entire mass of wood is protected , because the chemicals are penetrating and go to every fiber and molecule of the wood and not only in the surface or some milimeters underneath .

Why is impregnation important ?

There is no other way and method you can use to protect and treat your wood in its absolute entire mass and not leave unprotected areas , making it fully “bulletproof” for 30 to 50 years from all the enemies the wood has with amazing final results .

Can you Sand impregnated wood ?

Yes , you can sand your wood and do whatever process you want with a impregnated treated wood , because the wood’s “behavior” doesn’t change at all , but you should use gloves if you want to totally avoid the touch of the chemicals the surface will have .

Can you Paint impregnated wood ?

Yes , you can paint and use whatever finishing product you like after impregnation( you should give a little time ) but you should follow the advices of the professional who made the impregnation , to clarify you all the appropriate specifications according the chemicals he used .

Can you Stain impregnated wood ?

Yes , you can stain your wood after some time( a couple of weeks ) after the impregnation process and you should be very cautious with the advices you’ll get from the professional , in order to have the best results .

What is the Principle of impregnation ?

We use high pressure to push the chemicals we want to protect our wood , to penetrate deep inside to all of the mass filling every fiber and molecule , providing the maximum of protection for many decades wiτηout any damage at all .

What is the Difference between impregnation and emboding ?

The emboding of wood pretects only the surface and some milimeters underneath and not the entire mass , while the impregnation protects the entire mass without leaving unprotected fields at all , providing amazing durable results .

What is the Success rate of impregnation ?

You can have totall protection of your wood up to 98% after a year of the impregnation process with zero damage of of your wood and with very durable results .

Impregnation is maybe the only way for Maximum protection .

If you want to protect your wood and have the maximum possible , impregnation is the way you must follow .

The chemicals and salts with impregnation penetrate as deeper as we can inside the wood , so the protection can be the best . We cannot accomplish this goal of ours with any other way , than impregnation .

Using special pressure ovens , we “force” the chemicals to penetrate , to wood in all of its mass . So as you can imagine , if we want the impregnation to be perfect , we need to do it in a wood factory and this costs , unfortunately for the individual carpenters .

In these wood factories , the highly pressure “forces” the chemicals to go inside your wood and make it invulnerable to its “enemies . These pressures may reach 10 – 15 atmospheres according the wood type , the chemicals we use and the moisture of the wood .

Going to a factory like this costs some money , but the result is the best you can achieve . The chemicals are penetrating your wood to the maximum and the most important , remain inside the wood for more time .

When you’re about to go to one of this factory , to impregnate your wood , be very careful . You wood’s moisture must be below the 40% , if you’ll use oil soluble chemicals .

If your chemicals will be water Soluble ones we want higher moisture . More than 50% .

Is there another way except the high pressure ovens for impregnation ?

Yes there is . You can use a paintbrush or immersion , to paint and spread your chemicals to your wood pieces , but the result will be way less effective , than the impregnation .

As you can imagine , you can use a paintbrush all alone trying to do the “job” , but the wood’s mass penetration will be way smaller .

The same results , or maybe a little better you’ll have with the immersion .

If you leave your wood covered with the chems for some days – weeks , the chemicals will penetrate more than the brush , but not ideally . So if you want the better protection results with chemicals , impregnation is an “one way road” .

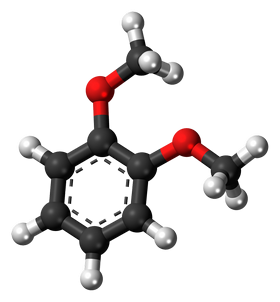

What are the Chemicals used in impregnation ?

The chemicals Types we use for impregnation are 3 and they are :

1) Water Soluble Chemicals .

2) Oil Soluble Chemicals .

3) Oils – Tar .( HIGHLY avoided – extremely TOXIC )

1) Water Soluble Chemicals .

The water soluble Impregrating substances , are mixed metallic chemical materials , mostly salts , but not only salts . These mixed chemical metallic materials and salts are penetrating inside the wood piece , by pressure from the industrial ovens .

So this method cannot be made by you , with a paintbrush or something like that . It’s kind of expensive for an individual to do , but it’s worth it for sure .

So what is happening when these chemicals are getting inside the wood ?

The metallic elements are reacting with the celloluse and the other inside tree elements and they prevent the salts to be “washed” away . They keep the chemical salts for much time inside the wood , so that the salts can protect your wood , for years .

So this method of impregnation with salts and other metallic chemicals , is more complex , but it keeps your wood in the better “shape” possible .

If you go to a very good and professional pressure oven , so that the chemicals penetrate the whole wood mass , you have done the best you could go to protect your woodworking project .

The Water soluble chemicals which commonly used are :

1) Cuprum salts .

2) Chromium salts .

3) Clorine salts .

4) Zinc salts .

5) Boron salts .

6) Fluorine salts .

7) Arsenic salts .

You may have seen a wood board , or something , having a light green color , a green “dust” on it . It is the arsenic salts after the impregantion and the appropriate drying after the inpregnation .

The arsenic salts are very good for the wood protection . It’s very effective for the bugs and it has many benefits .

We NEVER BURN IMPREGANTED WOOD . NEVER – NEVER – NEVER . The gas waste contains arsenic and it is very toxic .

The impreganted wood is very resistant to the outdoor circumstances and it can be used for many woodworking plans of yours , but you must never burn it , no matter what .

2) Oil soluble chemicals .

The oil soluble chemicals are way less toxic , than the water soluble ones and mostly are tar derivatives , which are dilute with several solvents . These solvents are petroleum most of the times and solvent tar . Of course depending the professional who is making the impregnation , many more solvents , can be used .

3) Oils – Tar . ( HIGHLY avoided . HIGHLY TOXIC )

In the oil area , we use Tar . It is the main chemical oil to use and its protection , is mammoth , but it’s toxic and i don’t suggest you to even think this protection path .

Tar comes from petroleum and it cause many – many SERIOUS health problems .

Usually the public services and the states use tar to the wood which it’s going to “live” outside and for many – many years . I’m sure that you have noticed the power supply’s agency log columns and the dark coating they have .

This is tar . Usually the part of the log , which is going to be inside the soil , has tar coating but in some cases the whole log column has tar coating . Here in Greece almost all of our Power Supply’s columns are full on tar , in all of their lengths .

AVOID it – AVOID it – AVOID it .

Do the impregnated chemicals , affect to the wood properties ?

Yes they affect the tree , the wood and your woodworking projects . These chemicals and in general this process we do to protect our wood , affect to the mechanical and other wood properties . Usually they reduce them , but in not a very significant grade .

How long does impregnated wood Last ?

Half a century is a realistic time period , but it depends from many factors , the type of wood , the drying of the wood after the impregnation , the type of chemicals we use , the depth of the impregnation from the pressure oven , the quantity of the chemicals which are remain inside the wood , the place your wood will “spend its life” .

The weather conditions and moisture for sure , concerning the “washing out” of the chemicals . In Greece , we have power supply log columns( unfortunately with toxic tar protection ) , which were placed in the mountains before half a century and more .

These tree columns were placed in the 60’s and they are in a very good condition .

To remind you that here in Greece our climate is very tough for the wood . We have sort but sometimes hard winters and many months of very hot summer .

Our summer high temperatures last for more than 3 months , till 6 or 7 sometimes and the sun is “punishing” the wood with very high temperatures for 12 hours a day .

This switching , from moisture at nights and the hot sun for 10 – 12 hours a day , “tests” the wood hard .

Keep up your woodworking life and launch your happiness to the stars !!!