When we’re talking for the best chemical finishing combinations , we should be aware that the chemical combinations are way more than the natural ones , because the modern products are countless .

In the chemical finishing ares i’ll include the natural oils , which are enriched and have chemicals inside them , for better drying , applying , protections and whatever else the manufacturer has put inside .

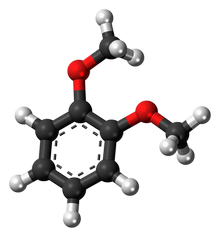

The boiled linseed oil( not the one we boil ourselves ) is considered to be a chemical material and not a natural , because it has several solvents inside , for faster drying .

The same happens to many teak oil versions , which have inside them UV filters , and several other chemicals to give to the teak oil , specific features .

The same happens to all of the natural oils . The manufacturers are using them as a base for many of their chemical modern finishing products .

The finishing mentality here is the exact same with the natural finishing oils and waxes and it’s this :

“ Begin our building into deepest – deepest in wood > proceed deepest > proceed deep > finish in the upper area and the surface of wood . “

The sanding approach is still the same . If you want the widest pores your wood can possible have , sand “aggresively” and then you can slightly smoothen your surface .

You can also use a hairdryer to warm the wood and raise its fibers more .

You final result in this chemical finishing area are kind of more complex , because the elements are so many and you should experiment to a small piece of wood , to identify by yourself for sure .

So let’s see some classical chemical finishings .

1) Boiled linseed oil + oil based Varnish . ( brush applying )

The boiled linseed oil has solvents and other chemicals inside for faster drying and you can combine it very nice with a capable oil based varnish , to have uniformity and strength .

The linseed oil is a base for many other chemical finishes and that’s why is a super basic oil for the chemical area of finishing .

2) Teak oil Mixture + oil based Varnish . ( brush applying )

If you want extra bugs – fungi protection and a nice oil based varnish , the teak oil is a perfect choice . The teak oil is very antifungal and you can seal it with a oil based varnish as an upper coat .

The teak oil mixtures , have Uv filters inside , anti moisture factors , several solvents , et.c and these mixtures are very powerful .The teak oil’s ability to protect from bugs( and not only ) makes it a base for many chemical finishing mixtures .

Linseed oil and teak oil are extreme significance oils .

3) Boiled linseed oil + Decking oil . ( brush applying )

Combine the abilities of the boiled linseed oil for your deepest depth and then , seal all this with a very capable decking oil mixture which may contain , teak oil , maybe some pure linseed oil , UV filters , tung oil , several hard waxes , solvens and other toughening factors .

The decking oil is the best and most strong edition of the oil mixtures . It’s focused to the tough sea – boating conditions .

The linseed oil will solidize the inside of the wood and the decking will penetrate enough , but it’ll seal and strengthen the surface , to a maximum level .

4) All kinds of oils + Oil based Varnishes . ( brush applying )

You can combine all the oil types – mixtures you can find in the stores with every oil based varnish , you like , with very good results .

5) All kinds of oils + oil based Paints . ( brush applying )

You can combine all the oil mixtures , you can find in the markets , with every oil based paint you want .

6) All kinds of oils + Polyurethane finish . ( brush applying )

You can combine all the types of oil mixtures , you can find with the sealing power of the polyurethane finishing and have excellent and extreme strong results .

Polyurethane literally is plastic and plastic is very strong to all the conditions .

The most classical polyurethane suggestions and more , in HERE .

7) All kinds of oils + Laquer . ( brush applying )

You can combine the abilities of the oils mixtures , with the gloss and crust protection of a nice wood laquer , to have a very beautiful and uniform finishing .

The musical instruments creators use laquers , very much .

Some classical laquers to buy , in HERE .

8) All kinds of oils + Synthetic Shellac . ( brush applying )

Shellac along with the laquers are the most capable wood finishings , that can give this “donut” gloss and uniform beautiness , in a wooden surface .

That’s why the musical instrument creators use these to , very much . There are very versatile and excellent for last coating .

You can find synthetic shellac in the stores with excellent features .

See some top shellac suggestions to get in HERE .

9) All the Water based Varnishes + Laquers . ( brush applying )

You can combine all the water based varnishes that have a good wood penetration and then use a fine laquer to seal your result .

10) All the Water based Varnishes + Polyurethane . ( brush applying )

You can use your water varnishes and seal the final result with a polyurethane , in order to get he maximum of protections , the polyurethanes provide .

11) All the Water based Varnishes + Synthetic Shellac . ( brush applying )

If you don’t want to use oils , but a nice water based varnish , you can use a synthetic shellac with more strength than the pure one and make a srong last general finishing .

12) All kind of oil based Undercoats + all the kinds of oil based Last coats . ( brush applying )

Try to combine chemical elements , that have the same as much as possible base , for their chemical formulas .

Oil based elements are bonding better with oil based elements .

13) All kind of Water based Undercoats + all the kind of Water based Last coats . ( brush applying )

The same applies , for the water based elements for your wood protection – finishing . Try your undercoat to have the same chemical formula with your last layers and you’ll see the difference to your result .

Same chemical formula’s elements , bond better and they last longer in time .

14) Polyurethane , can be used to any kind of Undercoat .

The polyurethane which literally liquid plastic , is the most strong element you can use to seal as a last layer , of your wood plan . Plastic is very strong .

You can use the so many types of polyurethanes , you can find in the stores , to any type of wood finishing you choose , with top results .

If you can “match” your undercoat chem formula , to your polyurethane one , even better .

15) Laquers , can be use to any Undercoat .

Even if laquers aren’t so tough as the polyurethanes , you can use them as a final touch to any undercoat , you have , giving this crust appearance .

You can use them even to a waxed wooden surface , if your appetite wants this for reason , but of course except a crust above your wax , it won’t do anything more to wood .

The wax doesn’t allow anything to penetrate inside , but you may want to crust your wax . You can do it .

16) Polyurethanes are the ultimate protector , last coat .

For the same reason with the wax above your wood , the polyurethane should be your ultimate last coating , because polyurethane is a plastic and plastic seals totally , making an impenetrable film to the surface .

17) Be careful with the Dyes – Stains that Change the wood’s Color .

When you want ot use a dye or a stain to change the wood’s color , you should be careful to what element you’ll use for your undercoat and last coat .

The dyes and stains that change the color have strong pigments inside and you shoud be careful , to get the exact color and shade you want , combining them with your other elements .

The above 17 ways and techniques , you can use only chemimcals for your wood finishing , are a basic mentality and approach , to avoid “surprises” and help you , be successful .

The chemical products you can find outhere , are countless and every manufacturer , makes his own formula for specific needs .

Make your experiments to secure the final results and proceed slowly .

Keep woodworking and happiness will be your final “coat” for sure .