Many people think that the nails , the screws and generally the fasteners we are all familiar with and have all in our houses , aren’t serious tools and maybe they “underestimate” them .

This is “not the case” and in woodworking the fasteners are extremelly serious helpers for the carpenter , amateur or not . Especially if he-she , is all alone and have zero help to accomplich a wood project .

So , let’s start and make an all time guibebook concerning the wood fasteners , in order to have a precious knowledge “database” , to use as a guidebook and “lighthouse” .

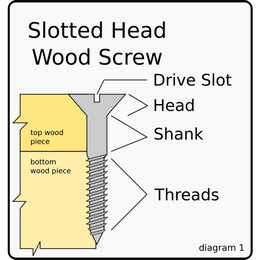

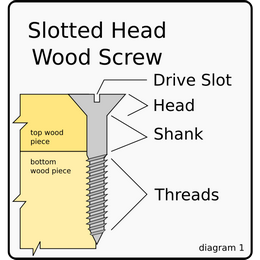

The fasteners focused for woodworking use , are several types of metalic pins or metalic screws having several type of heads and several types of threads , made from several types of alloys .

Make a check in HERE to see what best fasteners you can buy .

What are the fasteners , for Wood ?

The fasteners are helping the woodworker , to join two or more wood pieces together( or in other elements ) permanent or not , with several stability and securance levels , providing the ability to decompose most of the times .

What is 8.8 fastener ?

The 8.8 bolt is a bolt with nominal tensile strength of 800MP and a nominal yield strength of 80% , of the tensile strength , which is 640MPa .

What are the Types of Threated fasteners ?

The type of threaded fasteners are the bolts and screws .

What are the 3 Types of Threads , found in fasteners ?

1) The all types .

2) The UNC ( Unified National Coarse ) , threads .

They have longer pitch and bigger measurement .

3) The UNF ( Unified National Fine ) , threads .

They have smaller pitch and measurement , smaller threads , better locking and higher tolerances to heavy loads .

How do i Choose a fastener ?

You should consider the type of the material your fastener should have , you should know the load forces and needs , the resistance to several types of strengths , as twistings , expansions , the resistance to weather and rust contitions , et.c and some controlled tolerances it should maybe have .

How do you Fasten , Wood to Wood ?

According to the exact needs , your wood joining should have , you should choose the appropriate fastener to use . Sometimes you may need just some screws , sometimes some nails only , sometimes a threaded insert for maximum strength , etc .

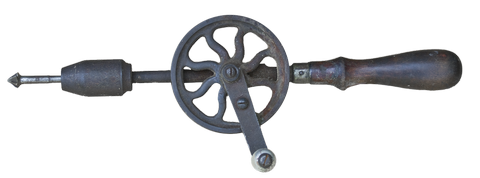

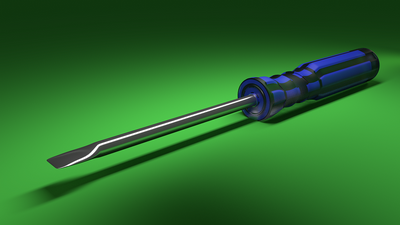

Can you Manually screw , into wood ?

Yes , certainly you can and i suggest you to always start manually , in order to be “surgical” precise and then after some screwing , you can continue with your power screwguns , et.c .

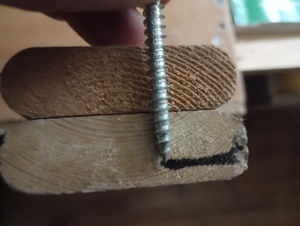

Why does , my wood Split when screwing ?

This may happen for many reasons , as your wood is very dry and stiff needing hydration or you may screw very close to the edge of your wood and the screw is very sharp .

How do you Stop wood Splitting , while screwing ?

You should make steady and not too fast screwing moves , the prehole drilling will help for sure and your bit should have less diameter than the screw shank tapered .

See in HERE how you can alternative nail or screw near the wood’s edge , without splitting .

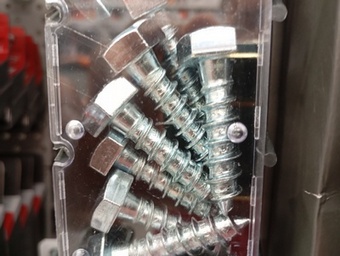

Is a Bolt a fastener ?

Yes , of course it’s a faster and it’s a non tapered fastener , while the screw are tapered fasteners that create the thread as you screwing .

What is the Best screw , for wood ?

The standart brass woodscrew or the stainless steel woodscrew .

What are the Best screws for wood , concerning their threads ?

Generally for the hard type of wood , we use screws with fine threads , because they don’t need more screw “biting” and for the softer types of wood , we use screws with coarse threads .

Can you use , Any screw in wood ?

Yes you can , but if you want to have the best results and don’t have future problems , you should use the appropriate screws for wood , which are designed for the specific features and nature of the wood .

In some cases the aluminum and the galvanized screws are not ideal and should be avoided .

Can you Screw , into Solid wood ?

Yes , you can screw into whatever wood type you want and for the very solid and high density wood , you should make predrills and have a pilot hole , for maximum precision and result .

Will screws , Crack wood ?

No of course not , this is not a general case for the screws and their performance into wood .

If you do what you should do accordingly to the wood you have infront of you , you go slowly and with precision , make your predrills maybe et.c , you won’t have a problem .

How do you screw into wood , Easily ?

You should use the appropriate screw type for the wood you have infront of you ( hard – soft , plywood , et.c ) , you can make predrills , you should begin manually and proceed with a power screwgun and you can also lubricate the screw thread , a little .

Do i need to Predrill holes , for wood screws ?

Yes in some difficult hardwood types , in plywood and in the industrial wood in general , because they have specific properties and needs .

If you want to be certain in a high grade that you’ll avoid the wood splitting , the predrills are helping very big .

Should i Nail or Screw , Plywood ?

The screwing has better “biting” results to the plywood’s mass , but your screwing should be very careful in order the plywood’s veneer layers , won’t get hurt .

Move – screw , very slowly and controlled .

Why screwing into MDF , is a tough job ?

The micro particles of the MDF along with its resins , are very splitting – sensitive to screwing and if you try to screw an MDF, your bit should be extremely sharp and maybe you should choose a brad and proceed very slowly .

If you lubricate a little you’ll screw easier .

What are the Best fastener for MDF ?

A brad with some yellow wood glue , is a perfect choice to use in the sensitive micro particle and resins mass , of the MDF .

Can you screw , into Plywood ?

Yes , you can certainly screw into plywood and the correct and ideal way is to make predrills , slowly and with the appropriate attention , not to interrupt the plywood’s mass violently and have problems .

Will Plywood , hold screws ?

Yes , it can hold your screws if it has the density it needed and you screw the appropriate screw to it , but you should be careful to the powers you’ll apply to it after the screwing .

What is the Best fastener for Plywood ?

The best fastener for the majority of the plywood types are the stainless steel ones with hellical thread .

How do you Secure MDF to wood ?

If you want to get a bigger holding security for your MDF and your wood join , you can use the popular yellow glue , or you can combine an epoxy two elements glue , to get the strongest connection power possible .

What Size screws , do i need for MDF ?

For the MDF , usually we use screws with the appropriate threads( they have their own specific thread ) having a size range between , the 40mm – 50mm and they usually are torx ones .

What screws for 18mm MDF ?

Usually you’ll need the 35mm – 40mm screws for a 18mm MDF .

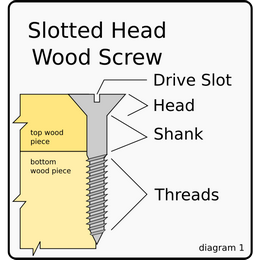

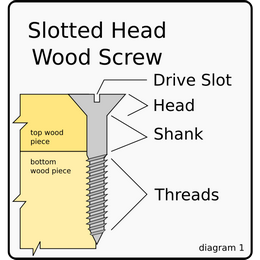

How do you Measure wood screws ?

For the Round head screws , you begin to measure from the flat outside .

For the flat headed , you begin to measure from the top of the screw .

What are the common screw Sizes , for Woodworking ?

The most common diameter screw size in the woodworking area is the range between the 6mm -10mm .

What is the most common , Torx screw size for woodworking ?

The torx sizes for woodworking are the : T6 – T8 – T10 – T15 – T20 – T25 – T30 – T40 .

What is the Rule , for wood screw Length ?

The general screwing length rule is this : you go from the thin to the thicker area and you penetrate only up to 2/3 of the second piece of your joint .

If the second piece you join together is 9mm , you screw up to its 6mm .

What is the Rule of Thumb , for wood screw Length ?

The thumb rule is this :

“The anchor length ( length of the thread in the parts you’re fastening ) , should be twice of the fastened materials thickness .”

If you have 2 boards of 1 + 1/2″ , the shaft inside the materials should be up to 3″ .

Does MDF , needs to Predrilled ?

Yes it does , because if you don’t prepare the fibers and resin surface , you’ll have fiber raising and maybe big problems .

Does MDF , need Special screws ?

Yes , it does and we usually we use screws for the MDF , with long and straight shank and with big aggresive thread .

How do you Strengthen MDF screw Holes ?

The use of glue is the answer in here . If you have the two elements glue , even better because you have to glue two different elements in here . The metal of your screw and the MDF’s mass .

Do you use Coarse or Fine screw for MDF ?

You use coarse screws for the MDF boards , because the specialized and “strange” mass of the MDF , which isn’t solid and uniform as the real wood’s fibers , need good “grabbing” from the coarse thread of your wood screw .

What type of fasteners is Used for Pressure treated wood ?

We use galvanized screws , stainless steel , copper and stainless steel bolts for the bigger jobs in the area of 6mmm to 12mm .

Do a Pressure treated wood , have to use Corrosion resistant fasteners ?

Yes , it’s needed to use corrosion tough and resistant screws – nails as the the copper , the galvanized , the stainlesss steel ones and an extra tip in here :

“The more chromium the stainless steel fastener has , the more stainless it is !!!! “

The chromium gives the stainless feature – characteristic , to the steel alloy and every chromium percentage above the 13% , the better .

The best stainless steel alloys are above the 13% and raise to the 18% – 19% for the most capable ones .

Can i Use Regular screws , for Pressure treated wood ?

Yes , you can but it’s not recommended because in long term you’ll face corrosion , stabilty and other general problems .

The galvanized , the stainless steel and the ceramic coating are way better and suitable .

Are Galvanized Nails , ok for Treated wood ?

Yes , they can do the job and this galvanize coating is very weather and other tough conditions capable . You need the stainless steel ones , the copper ones to avoid corrosion and rust .

What happens , if you use Regular Nails in Pressure treated wood ?

You’ll have certainly highly corrosion themes , followed by rust and eventually the mixture of corrosion – rust , moisture and the chemicals from the pressure wood , will give you serious problems .

Why need Certain fasteners , for Treated wood ?

The fasteners should be able to withstand the corrosion that will “attack” their metal and all the chemical reactions through time and eventually will cause serious rust issues .

Can you use , Zinc screws on wood ?

No it’s not recommended to wood and pressure treated wood , because they’ll face corrosion and rust themes , during time and there aren’t approved for the treated wood from the ACQ .

If you don’t have any other screw type you may use them , but have in mind that you’ll face rust problems in the future , especially if you’re near the sea or the moisture is high in your territory .

Are Zinc plated screws , ok for Outdoor use ?

No there aren’t very much because the coating they have , isn’t strong and resistant enough for the tough outdoor conditions .

You’ll face rust issues eventually and the zinc type of fasteners are mostly a “i don’t have any other fastener , so i use them” , situation .

It’s not “deadly” forbitten to use them , but the you should be aware the rust themes you’ll face .

How Long Zinc plated screws , Last Outside ?

This depends from the general weather conditions and the treatment this screw will have , during its “life” , but a decade is a realistic time period .

What Outdoor Bolts , won’t Rust ?

The stainless steel bolts are the most suitable for outdoors .

There is no element on earth that is 100% stainless and “immortal” concerning the wear from time , but a high chromium( 13% – 19% ) stainless steel fastener , will last longer than anytning else .

Will Machine screws , hold in wood ?

Yes they’ll hold generally and especially into hardwood , but it’s recommended to use the appropriate screws for the wood .

Are Machine screws , Stronger than wood screws ?

Yes , there are because they are made to join together metal and other materials( as steel and other metal alloys , carbon , concrete , et.c ) , way stronger than the wood’s mass .

What is the Difference , between a Wood screw and a Machine screw ?

The wood screw has a more coarse thread and a smooth shank , while the metal screw has finer thread to all of its body and of course the quality and the treatment of the metals , are totally different .

Are Joints , stronger than Screws ?

Yes , there are many joints which are more strong than the screws , with the most typical examples the mortise and tenon , the dovetails and not only .

Are Screws , stronger than wood Glue ?

This depends , even if many say that the wood glue is stronger . If you have the exact strong wood screw and a hard type of wood , you can join wood pieces together , very – very strongly .

The wood glue when it dries becomes stronger than the wood itself , but i think a very strong and appropriate wood screw and a high density wood with strong fibers , can bond very tight together .

I think this is a very close bonding “battle” , between the wood glue and the screws .

Why carpenters use Nails , instead of screws ?

The nails are cheaper than the screws , there are more easy to place them into wood and if you’re capable enough to nail them strong and angled , in some cases the nails are providing equal wood joining , with the screws .

Why do Nails hold better , than Screws in some cases ?

This isn’t totally true and even if the nails have more tensile strength , a good and appropriate screw with a nice thread shape , can hold and tighten two or more wood pieces together , very strong .

More stronger than a nail , which if you force big power long its nailing direction adn with some small hit , it may start to tremble and lose its bonding power .

Remember what is happening to some old – vintage wooden chairs ( especialy in the coffe shops ) , made with nails only , from time and hard use .

You sit and the whole “thing” is moving back and forward like a jelly .

When should you use a Nail , instead of a screw ?

The nails are used moslty for temporary joints , there are removable if you like ( easier than a screw ) and there are more adjustable , than the screws are .

Nails are easier to use and you can extra secure a joint , along with some wood glue maybe .

The screws are providing more stability to several forces and from several directions , providing a joint of big stability and long lasting , holding the wood pieces in the exact spots , you screwed them up .

What Direction , is a screw stronger ?

You should try to screw your screws , across the grain of the wood and radially to the wood’s rings if possible abd less along its grain , in order to grab the fibers better .

Will screws , Hold in wood Glue ?

Yes they’ll hold almost all the screw types , but if you have stainless steel screws you won’t have very good bonding – holding power .

How much Weight can a wood screw hold ?

A 6″ long screw can hold a ton of pure weight , into one feet of thickness oak wood .

What Kind of screws , will not Split wood ?

Its’ not so much the type of the screw you should have to avoid splitting , as the type of wood and your screwing actions to screw your screw .

The sharp screw are more dangerous for wood splitting , in general .

Why do Sharp screws , Split wood ?

The sharp screw are forcing the wood’s fibers with bigger twisting forces they can handle and all this happens fast , because a sharp screw penetrates easier than a more wide one .

Can you put screws in wood , Without drill ?

Yes , certainly you can and every type of wood outhere doesn’t need drilling and pilot holes , in order to use your screws , successfully .

Usually we predrill in the tough type – hardwoods , in the industrial wood , but whenever you judge that you need to predrill , you should do it .

The wood drilling makes the job easier and gives extra precision .

Should you Lubricate wood screws ?

The screws lubrication makes the screwing way easier , for the manual screwing and the power screwing with your power screwdrivers , screwguns , et.c .

For the hardwoods and the tough density woods , i can say that lubrication is maybe necessary and welcomed .

The only you should be aware in here is that because the screwing becomes easier , you should not screw very fast , in order to be precise and not damage wood in any way from the fast screwing .

Slowly and totally controlled is the “name of the game” in here .

What is a good Lubricant for wood screws ?

You can use whatever lubricant you want( teflon , parafin , olive oil , et.c ) and doesn’t affect the wood and the metal of the screw , with the beeswax being a top lubricant .

If you want ot see what i use to lubricate my screws and how i learned this , go HERE .

Can you Drill bolts , into wood ?

Yes you can and the hardwood will need the drill pilots to secure the maximum precision .

Is Stud , a fastener ?

Yes , it’s surely is and an exceptional one . This metalic stick with its two sides able to screwing and tightening the wood , provides amazing stability and strength .

Is Dowel , a fastener ?

The dowel is a fastener helper and it’s designed to support a joint , not keeping it together tight and strong all alone .

How do you Secure something , to wood ?

The wood glue , the dowels and the right combination of the classic wood joinery ( mortise & tenon , dovetails ) along with the big help of the right fasteners , can secure wood , extremely big .

Imagine a dovetail joint , having an entire dowel , penetrating all of the joint’s length . This would create a “beast” joint , extremely stable and strong .

The combinations are countless , depending your imagination .

What is the Strongest wood Screw ?

The strongest screw for wood is the one with an externally driven hexdrive or maybe a square head , with tapered point and coarse thread .

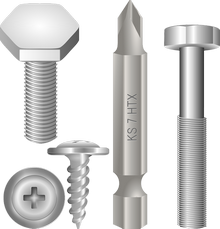

What is the Difference , between a fastener Bolt and a Screw ?

The screws are full thread designed , while the bolts may have shanks without threads and the bolts are used with nuts , always .

Are Bolt or Screw , Better for wood ?

The bolts can handle more weight than the screws and general big forces in every angle the wood joint can be “tortured” . There are stonger made in a primary level and the nuts help them very much to tighten the wood joint , better than a simple screw .

The screws are very capable but not as strong as the bolts , because they “bite” the wood’s mass and fibers very tight and stronger ( more than a nail ) and it can handle very big tensile forces on it .

Why the Nails lose against the screws & bolts ?

The nails are a faster and easier fastener than the screws and bolts , but in some cases they can lose their tightening strength of the entire wood joint . Especially if you put forces – you hit them along their nailing direction .

If you hit a wood joint with only nails with a hammer lightly , along the direction you nail it , the joint starts to loosen and eventually , you’ll unscrew the two wood pieces .

What can i Use , Instead of screws ?

You can use all the other fasteners ( nails , inserts , stud ) , bonding tapes , several wood glues , zips , maybe ropes and of course all the variety of wood joinery .

What is the most Popular fastener for , Screwing wood ?

The flat headed screw is the most common fastener you can use and i don’t think there is a house ,which doesn’t have a couple of them or bigger quantities of any size .

The fasteners in woodworking are super and extremely useful equipment , anybody can use to make a simple wood joinery , permanent or not .

You can create amazing entire wooden furniture using the amazing beautiness , antique nails and screws , or use them for extra security , along with wood glue .

Keep woodworking and the happiness will permanent be attached to you , “with screws , or nails” .