If we agree that the combination of hand tools and power ones is the best woodworking approach , the bandsaw power tool , cannot be missing from a carpenter’s tools machinery .

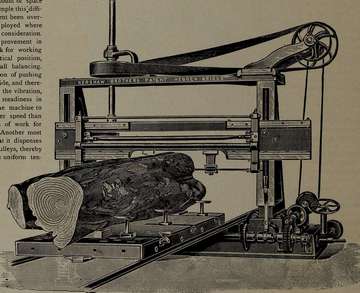

The woodworking bandsaw power tool , is a cutting – ripping wood machine , consisting of two metalic wheels , which rotate a flexible metal strip-blade(of several TPI’s : teeth per inch) , under tension .

Is a Bandsaw a Necessary Woodworking Tool ?

Yes , it certainly is because it gives you the ability to cut – crosscut – rip too many wooden boards( 10 boards – 20 in a row ) and continuously , in much less time and in much less effort , than using a rip hand saw .

** See my Top bandsaw suggestions & some tips , in HERE .

What a Woodworking Bandsaw does ?

Using the bandsaw , we can cut wood in all of its 3D dimensions ( lengthwise – widthwise & reducing their height / thickness ) , rip wood – boards lengthwise and cutting curves – circles .

The most common use is the lengthwise boards cuttings , resaw timber , veneer corrections , curve cutting , wood panels matching and thinner wood in general , but you can do whatever you want .

Can you Rip a Board , with a Bandsaw ?

Yes , surely you can and ripping boards is one of the bandsaw’s major job , which does very accurate , correctly , continuously and in a much less time and less effort than a rip hand saw .

Can you cut Straight Lines , with a Bandsaw ?

Yes , you can do it very smoothly with a nice blade and be very accurate .

How Thick Wood , can a Bandsaw cut ?

A powerful enough(2HP) bandsaw can rip – resaw whatever thickness wood you have in your workshop and has a wide opening of 17″ , if you resaw 10″-12″ and more wide , wooden boards .

Most of the stock bandsaw fences won’t be very efficient for these types of widths , so most of the times you’ll need to make or buy an extra fence and clamp it to the bandsaw table .

Is a Bandsaw Better , than a Jigsaw ?

Yes , for sure it is because it cuts way more accurate straight lines than a jigsaw . Of course the jigsaw and the bandsaw are different power cutting tools , making different jobs .

In the area of the straight lines cutting the bandsaw is better , in the area of more detailed and difficult patterns , the jigsaw is way better and capable .

What are the 2 Types of Bandsaw ?

The 2 types of bandsaw are the vertical and the horizontal ones . The vertical are the “classical” ones you use for ripping , crosscutting , et.c and the horizontal are the ones you see cutting – slicing wooden boards from logs , in several thicknesses .

How do you know what Size Bandsaw to get ?

This decision is related to your ripping needs as woodworker . If you do small mainly ripping jobs and not with hardwood , you won’t need a very powerful and big bandsaw .

A bandsaw of 14″ would be just fine for you . If you do more heavy-duty wooden board ripping and with several types of wood – hardwood , a 17″ and a 2HP+- , will suit you better .

A more powerful bandsaw with a capable blade , cuts “cleaner” , doesn’t gets “tired” and you avoid clogging easier .

What to know , before buying a Bandsaw ?

If you don’t want to waste money before you buy a bandsaw , you should be realistic concerning your woodworking needs and the exact use of your bandsaw .

If you do only small and medium size carpentry jobs , you won’t need a super expensive bandsaw . If you do more advanced or you’re a professional , you’ll need something more powerful and resistant to heavy-duty use .

What is the Main Danger with the Bandsaw ?

The main danger with the bandsaw , as for all the hand and power tools in my opinion , is the very serious or not hurting yourself or others , by lack of seriousness and focus while you’re acting woodworking jobs .

You can get hurt pretty badly your fingers , hands , arms , face from a wooden fragment , while ripping – cutting with your bandsaw . Even death from extreme bleeding can be caused .

I’m very strict concering the safety in woodworking and see my general safety mentality in HERE .

What are the Maintenance needs of the Bandsaw ?

I have a “golden” rule for the correct maintenance of the woodworking tools .

“Follow exactly the instructions of the manufacturer , don’t listen the random “experts” specialists from “centuries” of experience and if you have questions , ask the manufacturer . “

Never lose the manual , follow the manual and use e-mails for direct contact with the manufacturer .

Every single bandsaw brand , type , every country – continent the brand sells , et.c , has its own specific features . Fullfil these specific features , by following the exact orders of the manufacturer .

My entire maintenance approach , i try to follow , is HERE .

Keep woodworking and gain the best life’s approach which is happiness .