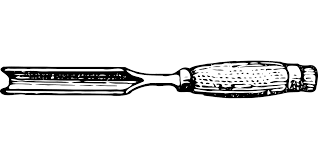

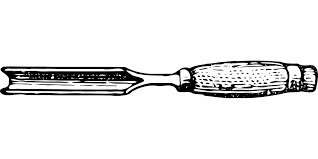

The carving of wooden surface is always a serious woodworking job and when we talk for curved inside carving jobs , the carving gouge is for sure and essential assistant for the carpenter .

For many carpenters , the gouge is the most essential carving tool .

No matter if you’re amateur or a more experienced woodworker , the correct use of the carving gouges is a serious advantage . These hand tools are designed to to this job , in a very accurate way .

The carving gouge is a woodworking hand tool , similar to the chisel , that consists of a special design handy wooden handle , attached to a sharp blade of several lengths and widths , which has its other side , sharp , curved with several sweeps(curvature) , bevels and be V-shaped or U-shaped .

See my top gouge suggestions for all pockets , in HERE .

What gouges are Used in carving ?

The carving gouges are used to slice – “dig” – shape very precise and fast , small or bigger peels of the wood mass we don’t want , in order to shape it and we can do this in types of surfaces(concave , et.c ) where a flat chisel’s corners , couldn’t fit to do the job .

A flat chisel cannot “penetrate”- to “sneak” , into a concave surface of a bowl , a spoon , et.c , to slice it , to shape it . Its edge corners would stuck in the curved – concave surface and we would have a problem .

The carving gouge can do the job very easily and with the accuracy we want .

How do you gouge wood ?

You very carefully , slide – “dig” your carving gouge to the curved pattern – design you want , in order to slice the exact wood you want to slice , most of the times using your hands power only and try to make a uniform motion from A to Z .

Sometimes you may use a mallet for help , but if you want “surgical” precision , you use only your palm – hand , powers for the job .

What are gouges made out of ?

As all the carving – shaping woodworking hand tools , the carving gouges are made for special metal alloys , having different levels of hardening concerning their targeting use .

The “old days” they used several carbon stell alloys , but not so much anymore , because they need more often sharpening . In our days the HSS ( high – speed steel ) is a very common metal alloy for a gouge .

Cryogenic alloy steel and other kinds of it are constantly tested .

Is a gouge , a Chisel ?

Yes , a carving gouge is a chisel which in general , is especially shaped to have a specific edge curved design and be metal hardened for precise woodworking carving , in curved and concave patterns .

What is the Difference , between a chisel and a gouge ?

The chisel has straight cutting edge , it isn’t flute curve shaped as the gouges and of course it doesn’t have side wings to carve wood .

How many Types of gouge are there ?

We seperate the gouges in many ways and we have many types of them , concerning their general width , their sweep , their bevel(single or double) , out-canel or in-canel , full sized – medium sized – palm holded , bent gouges or skew ones , V-shaped or U-shaped , flat handled or not to prevent the rolling above the workbench , et.c .

What are the two Basic types of gouges ?

The basic types of gouges are two , concerning their general width measured in mm and their sweep , also measured in mm .

What does Sweep mean in gouges ?

The sweep feature of a carving gouge is the measurement element we use to define the curvature and the shallow shape – radius of the edge of the gouge .

What are carving gouges , Sized ?

You’ll find the carving gouges sized , having two numbers on their handles , like this : “X/Y” . These 2 numbers mean :

1) The X , is the sweep of the gouge and the range is between the : ( #1 – # 16 . )

Attention in here : the largest numbers of sweep ( #13 , #14 – #16) have a V – shaped design and not a U-shape .

2) The Y , is the exact width of the blade .

Both are measured in milimeters , (mm) .

What do numbers Mean on gouges ?

The two gouge numbers on the handle , combined together they define the shape and design of the cutting edge’s curvature and the radius of the camber , your gouge has .

Don’t be confused , just have in your mind this : As the sweep number (the 1st) gets higher , the radius of the camber gets more keen and not very shallow .

What is the cutting angle , of a carving gouge ?

Usually and for general woodworking carvings we use a single bevel carving gouge with their cutting angles to fluctuate between the 15o for the softer types of wood and the 20o for the harder ones .

See what i mean saying the types of wood in HERE .

What is a Spindle gouge ?

It’s similar to the bowl carving gouge , but it has serious differences . It has more wide and flat flute shape , it doesn’t have cutting “wings” as the bowl gouge and needs less frequent sharpening needs .

It can reach small – “stiff” , detailed bowl( and not only ) areas very easily and make elite carve patterns , while the bowl gouge cannot .

You can sharpen its edge to be really very thin( and fragile ) in order to be very detailed .

What is the the best angle for a Spindle roughing gouge ?

The spindle gouges are having an 40o – 45o degrees angle , most of the times .

How are spindle gouges , Measured ?

You measure the width of the entire metal bar , they’ve been made .

What is an Ellsworth gouge ?

It’s the type of gouge which is very keen concerning the definition of its curvature and it has its side “wings” more higher and longer side wings , giving a more V – design generally .

It’s like the Irish type gouge and with these longer side wings , you can fleece – scrap wood more easily .

What is the angle of the Ellsworth bowl gouge ?

We usually slide – “dig” the ellsworth gouge to a 40o – 45o degrees angled to the wood piece we work with .

What is a Bowl gouge ?

A bowl gouge is the type of gouge we use to carve and shape an entire bowl to a lathe machine . It consists of a wooden handle attached to an axis , which is central flute shaped and its edge is beveled angled making a sharp cutting edge , for the lathe use .

See some of my top lathe suggestions in , HERE .

What gouges i need for bowl carving ?

The variety of the inside curved flutes for a bowl gouge , are the V – shaped flute , the U – shaped deep flute or the parabolic shaped , which is a super flute type gouge and the latest gouge shape evolution .

What is the best Size bowl gouge ?

For generic use a 5/8″ and a 1/2″ are just fine for bowls .

How are bowl gouges Measured ?

You measure the entire flute metal across the bar , right after the end of the round shaped tang .

What is the best angle for a bowl gouge ?

Of course there are no “unbroken rules” in here , but a angle sharpening range of 35o – 70o degrees includes all the sharpening angle variety for your gouge . More detailed we have :

1) The traditional bevel grid , is around the 45o .

2) The fingernail bevel grid , is around the 50o -55o .

3) For more tiny bevel grid we have a 60o – 70o degrees sharpening bevel .

All these numbers are very flexible depending your way you use and handle your bowl gouge .

** The Grid is the profile – the bevel angle – the side “wings” of the gouge .

How do you Measure the angle of a bowl gouge ?

We usually measure the bowl angle with a protractor .

Do i need a bowl gouge ?

Yes , you need some bowl gouges because they can remove fast the wood you need in your lathe , in order to start shape and create your bowl and it can create the entire bowl without any other tool help .

How do i Choose a bowl gouge ?

The quality of the metal alloy ( a HSS steel or a cryogenic one ) , is very important in order to sharpen less lften and have the carving results you want and a nice and comfortable wooden(usually hardwood) handle , are basics .

Above all , as all the hand tools , the feeling in your hands , should be supreme and very comfortable from the first touch .

Can you use a spindle gouge for Roughing ?

No , you cannot because you’ll damage the metal of its edge – tip , which isn’t shaped for this specific job and it’s more general fragile .

The spindle gouges have a more fragile tip(fewer metal around) which makes them more vulnerable to , but they can be modified , as a bowl gouge , changing its bevel , et.c .

The spindle gouges are for more elegant – detailed wood carvings .

Can you turn a bowl , with a Spindle gouge ?

No , you cannot shape an entire bowl( especially the inside) with only a spindle gouge , because it’s more fragile having more thin edge , which can cause even the total destroy of the gouge , being dangerous for the carpenter .

The spindle gouge is an elegant and more fragile gouge , made for the more detailed and “surgical” missions . It isn’t made for removing fast and big masses of wood .

What is a Spoon gouge ?

The spoon gouge , which looks like a kitchen’s spoon is made for deeper and very complex carvings , their axis is bent and not straight , they’re U – shaped and there ‘re maybe the expert for concave carving and shaping .

What is the Difference , between a Turning gouge and a carving gouge ?

The turning gouge is larger than the carving one and its usually used for removing a lot of wooden material in your turning lathe , making coves and beads .

How do you Sharpen a gouge ?

You can sharpen gouges manually using leather strops , a little compound , et.c , but i recommend you to use a sharpening jig .

Keep woodworking and happiness will be a result among others .