In the woodworking activity the main and basic element is wood , which originated of course from the trees and without the precious help from the hand saw , we cannot do much .

If you don’t have something to cut and seperate the trees from the wood pieces you like , you can only watch and “admire” wood on the trees and yourself , “crying”(!) for not been able to have it .

The hand saw is a metalic steel blade of several widths , lengths and thicknesses , attached to a wooden(mostly) handle . This blade in one of its side , it has cutting “teeth”( as the shark’s maybe ) which can cut – seperate the wood’s mass , using the forward – backward sawing movements , from us .

Usually the blade of the hand saw is made from several steel alloys , to give them specific features and the handle is wooden , but you can find plastic handles , et.c .

The blade is attached to the handle mostly with screws , or it’s pressed to it with rivets for more stability . The wooden handle is protected by a crust type varnish , most of the times .

I’ve written a mindset approach about the best saw for home projects , read it in HERE .

Are there any Specific Hand Saw Features , I should be aware ?

Yes , there are and these are :

1) Hand Saws with Ripping “teeth” .

This type of saw “teeth” are made to cut wood , along with the wood’s grain and they cut wood’s mass , having the “philosophy” of the chisels . They cut by pushing through – inside the wood’s mass . You may know them as “ripping” saws .

2) Hand Saws with CrossCut “teeth” .

These saws cut the wood’s mass , across the grain of it and they have the cutting “philosophy” of our common” knife” . They seperate mass while they’re moving .

3) The TPI number .

What is the TPI and how can i choose the appropriate for my cuttings ? The TPI is the “teeth per inch” number for your hand saw and it shows you , how many “teeth” has your saw in one inch .

It is a very significant number because it shows you , the ability for accuracy , your hand saw has . In here there is a “law” , you should know , in order to choose the appropriate saw for the specific carpentry job , you want .

This “law” is : ” more teeth , more accurate cuttings ” .

If you observe the hand saws for cutting big logs , they have big teeth with big distance between ( to seperate more wood mass ) and way fewer number , than a “common” saw .

The above 3 parameters are significant to know in a hand saw , in order to choose the right one .

What is the most Common hand saw and what is it Used for ?

The most common hand saw , all houses have and all people are familiar with , is the wooden handle hand saw with medium TPI for generic cuts and generic teeth design to cut along with grain(rip) and across(crosscut) .

How many hand saws exist and Why do i Need many ?

There are many and different hand saw types with different features and if you want to make very good several cuts with easiness and accuracy , you should have some of them .

All the wood cuts aren’t the same concerning the accuracy , the easiness for the carpenter and the “surgical” decorative detail he wants , that’s why we have many types of hand saws .

A specific type of saw , won’t do all the cuts well , but it can do the cut which was designed to , very well . So yes , you can cut your wood with every saw you’ve available ( a rip type to make cross-cuts , et.c) , but the “job” won’t be perfect .

Basically we have the Panel Saws , the Back Saws and the Frame Saws , the Japanese style ones .

See all my List with the Top panel – back and frame saw buying suggestions , in HERE .

What are the Basic hand saw Types , for a woodworker ?

1) The Rip Panel Hand Saw .

This type of saw is a panel one and it’s designed for cutting the wood’s mass , along with the grain . You can find them in many lengths and sizes , between to 20” – 30” . Try to have some of them with different lengths and TPI’s , to cover all the wood’s varieties .

2) The CrossCut Panel Hand Saw .

This saw is designed to cut wood’s mass , across the grain . Their “teeth” are like the knives ones , to seperate mass and they are smaller than the ripping saw .

3) The Rip DoveTail Back Saw .

This is a basic joinery saw and you can identify it from the piece of metal it has on the opposite side of their “teeth” . This metalic supporting piece , is to make the blade of the saw more stable while you cut . They cut along with the grain and they are in 10” lengths more or less .

4) The Carcass Back Saw .

This is a longer back saw which is a crosscut one . It cut the wood’s mass across the grain and it’s the one you see the most , in the creation of wood joints . It has small “teeth” and it creates joints very accurate and “clear” .

5) The Rip Tenon Back Saw .

This saw makes longer tenon cuts than the dovetail saw width and that’s why you should choose it for your tenons cuts . It rips mass along with the grain and it’s one of the largest saws you’ll have . At your beginning you may not make so long tenons , but eventually you’ll need one for this specific tenons job .

6) The Miter Box back Saw .

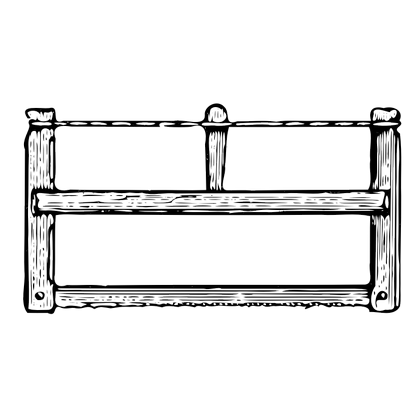

When we want to make 100% accurate degree angle cuts(90 – 45 – 75 degrees) , we use the miter box which is a frame , having these angles “carved” – premade on it . We put in these notches , our long back saw and the cuts are very “clean” and accurate .

See some top Miter box bying choices , in HERE .

7) The Coping Saw .

This saw you’ll remember it , from your school carving years . The coping saw it’s a frame which stretches a cutting blade inside it , in order to make curved cuts and “inside a board” difficult decorative ones .

8) The Frame Saw .

This isn’t a super urgent saw , you should have and it’s mostly a “traditional vintage ” saw . It’s a large coping saw which can cut curves and if you use a big blade , can cut straight lines also .

9) The Compass Saw .

This is a very useful saw to cut bigger wood pieces than the coping saw , inside a wooden surface and starting to cut from a predrilled hole , you would have made .

10) The Japanese Style Saw .

It’s may favorite for very detailed and accurate cuts . It has a big TPI and it’s very easy to use for “surgical” cutting .

Can I cut Engineered Wood Types with a Hand Saw ?

Yes you can cut any engineered wood you want , except the MDF , because it has most of the times a slippery surface ( for decorative reasons ) and this could be very dangerous for your safety .

The other engineered wood types ( particle boards , et.c ) have more cutting “grip” to start cutting , but the MDF don’t . In general , if your wooden surface is slippery , avoid ot make cuts with hand saws .

Should I have a Specific saw blade to cut Engineered wood ?

No you don’t need to have , the same you use for all your wood cuttings , you can use to act – cut engineered wood . As i’ve said above , avoid to cut slippery MDF’s and slippery wood’s surfaces , in general . The hand saw blades are made from steel alloys and they can cut from the “softer” type of wood to the “harder” one .

Is engineered wood , Harder to cut with success ?

No , it’s not . The engineered wood as the particle boards , the plywood , the marine plywood which is strong for the sea , aren’t harder than the natural wood pieces .

Only the MDF boards which most of the times have a very hard layer on their surfaces , are hard to cut with hand saws.

I won’t suggest you to cut MDF’s(very slippery outside) , but if you’ve cut in the past any , you should remember that when you passed the external hard – finishing layer , the rest of the MDF board , was easy to cut .

The only thing you shouldn’t forget when you cut engineered wood ( especially plywood ) , is to clean very carefully your saw blade after .

The engineered wood , is wood combined with resins and glue and this can damage your saw’s blade .

ATTENTION : Don’t confuse the engineered wod with the cement + wood fibers you may find in the markets .

If you like to learn more for the engineered wood , see in HERE some .

How can I cut “hard” wood without Burning the wood and my hand saw ?

If you want to prevent your saw’s “lighting – burning” from the intense friction while you’re cutting , the continuous cutting breaks combined with wood and blade checking , is the correct “path” . Don’t cut a “hard type” of wood , at once and use “gentle” cutting power , not brutality .

It needs correct cutting technique , not muscle power . And of course to let your saw’s blade to “rest” and cold .

If i saw Rust on my hand saw , can i fix the problem , Alone ?

Yes you can , no matter how big or small is the damage from rust . You should use all the necessary equipment it needs to clean totally and 100% the rust , from the metal .

You should use your sandpapers , maybe some “light” files if the rust is deep , your sanding tapes , whatever it needed to clean the metal form the rust .

Not even a tiny – nano part of rust is allowed . Take your time , begin with the roughest rubbing equipment , continue with the lightest and don’t stop , till the job , is done .

Make small detailed and fully control rubing moves . You don’t want to hard the blade’s “healthy” metal and the use of some oil to assist the rubbing , will help . Oil “soaks” the rust’s molecules , to be cleaned easier .

What is the “secret” Maintenance Tip for my hand saws ?

1) Don’t storage your hand saws inside toolboxes . The unavoidable touch with the other tools , will damage their “teeth” .

2) Storage them , “hung” by a pin οn a wall , or a frame .

3) Always check their wood – metal connections and make stability corrections if needed .

4) After the wood cutting , clean them from the wood’s fluids . Cypress for example , is full of natural resins .

5) Water – Moisture is an “enemy” for both metalic and wooden parts .

6) Don’t throw the saw on the floor and don’t throw them in general . Their “teeth” are sensitive and if they bent your cuttings will be awry from the side of the “teeth’s ” damage .

Keep acting Woodworking and make yourself happy and relaxed .