In the woodworking activity , no matter if you’re an amateur or a professional carpenter , you’ll have to do many types of actions and processes with wood . One very basic and essential process , is the wood sanding .

You cannot avoid totally to avoid this process , so you should know the entire sanding process and some “secrets” of it , in order to complete , correct and perfect woodworking projects .

You can adjust it and bring it to your needs , but you cannot avoid the sanding process totally , while you make a wood plan . Wood sanding is a woodworking column .

Wood sanding is the process of rubbing a wooden surface in the direction it’s needed , using pressure power manually( by hand ) or mechanically( sanders , belts , et.c) , in order to shape its pores smooth and flat , into the exact level you want , for the specific woodworking job -design , you have to accomplish .

What is the woodworking machinery i use for sanding ?

For the wood sanding we use a wide variety of manual wood tools as sandpapers , wool steel , abrasive sponges , abrasive pads made of several types of materials and have a wide range of grits , from very rough to the finest possible .

In the mechanical sanding area we have all the types of sanders ( orbital , et.c ) and all the variety and of sanding belts , having all the variety of coating abrasive elements and grit .

What is the Best way to sand wood ?

Even if there is no unbreakable rule in here , the best and correct way to sand a wooden surface is to rub – sand along ( and not circular ) with the wood’s grain , back and forth , “eating” wood’s “flesh” without disturbing its molecules structure .

Can you sand wood only by Hand ?

Yes , you can sand only manually wood using a big variety of sandpapers , abrasive pads , et.c , having the advantage of using the exact physical power it needed in a micrometric scale , to do the sanding job your current carpentry project requires .

What Tools do you use for sanding ?

There is a wide variety of sanding machinery for sanding as sandpapers , sanding belts , several types of sanders , orbital sanders , pulsating sanders , steel wool for minor sanding fixings – erasings , abrasive pads , abrasive sponges .

Depending of the surface you have ( big or smaller ) , you use the appropriate sanding tool and of course you can make whatever combination you want .

Does sanding direction matter ?

Yes , the direction of our sanding moves matter , because when we sand wood no matter what sanding way we choose , we “eat” wood’s “flesh” . The wood molecules in its surface ( and not only) are structured – directed with a specific way .

If we want to have the best possible smoothness and not affect in wood’s general density features , we try not to harm this molecules direction – structure .

That’s why it’s better to sand wood along with the wood’s grain – direction . If for a specific area the grain is circular , we sand circular .

Let the wood guide you . It’s the best way .

What to do before sanding ?

Always have in your mind the goal you have to accomplish with your sanding techniques and what shape , what smoothness and what flatness you want to give to your wooden surface , for the specific woodworking design you have .

This is very important and this will be your guiding “lighthouse” , to use this sanding technique or the other .

If you don’t want to give perfect smoothness to your wooden surface , you won’t use the finest sandpapers to make it “glass” smooth .

If you won’t to leave the wood’s pores totally open in order to “suck” the biggest amount of linseed oil ( as i do ) , you shouldn’t use fine grit sandpapers , at all .

Your “target” and what you want to do , is the correct approach in here . Adapt and improvise to get the exact result you want , not “what in the coffee shops say” .

Of course before you start using any of your sanding machinery , you should make a testing check of its performance to a small wood piece , similar to the one you’re about to sand .

There “millions” of sandpaper brands , belts , abrasives having a “millions” types of grits .

Should you push down , when sanding ?

Yes , pushing down pressure is needed when you sand a wooden surface and you should adapt micrometrically your pressure power to the type of wood you have , the grit of the abrasive you use and how fast and delicate you want to sand – “eat” your wood’s “flesh” .

Remember in HERE the 3 basic types of wood .

Always adapt to the circumstances , make small steps and between these steps make quality checks of your work .

The small steps give you the ability to evaluate the sanding process and fix a problem in its beginning , not when it’s too late .

Is it better to sand wood , Wet or Dry ?

It’s a wrong apporach to sand wet wood even if you’ll have less wood dust , because when wood fibers will dry they’ll have completely different sizes – shape , usually smaller from contraction .

This will affect for sure to the final result of the sanding process and to the general design you expect .

Can you sand Raw wood ?

Yes , you can certainly sand raw wood , but you should have in your mind that the raw – very rough wood surface will consume many sandpapers or whatever , to bring it down to a more fine – smooth state .

Always make safety checks for pins – screws , et.c inside the wood’s mass , when you deal with raw wood you find in the forests , et.c .

What is the Dry sanding technique ?

We try to remove the wood’s inside moisture or any other coverage – finishing of the wood , in order to start sanding it , more effectively and have a stable result .

What is the Golden Rule of sanding ?

Begin slowly with the roughest grit you want using little push – down pressure , make a first brake to check , continue escalating to the finest grit your “mission” needs adapting your power pressure till the “finish line” and never neglect your face mask .

What is the Process of sanding ?

1) Have a clear vision of what your wooden surface needs to be after the finish of your sanding , for the specific woodworking design need .

2) According to your sanding goal , deside what sanding machinery combination you’ll need for the job .

3) Gather these sanding machinery , close to you .

4) Place your wood in your workbench stable and comfort for you .

Some top workbench bying suggestions in HERE . ( + holdfast clamps , et.c )

5) Assure that your wooden surface , is “clean” from any external factor ( old / new coatings , hard / sharp elements , et.c ) and be completely dry .

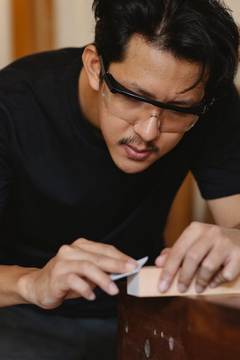

6) Wear your face mask – eyeglasses , maybe gloves if you’re comfortable with .

7) Start using the roughest abrasive grit and escalate to the finest you need and want for the exact smoothing – flattening job .

8) Make “countless” brakes , for progress checks , design compatibility checks and take a breath .

Use “good” light , your touch for this checks and maybe some extra wood machinery to check flatness , et.c. , straightedges , winding sticks , squares , or whatever . “Listen” to the wood , adapt and always improvise .

9) Continue till the finishing correct point you want and your currect design requires .

How do you sand , for Beginners ?

Make all the sanding steps very slowly in order to stay focused , make the road from A to Z very progressivelly and with feeling , learn to “listen” to the wood and its reactions when you sand it and have your “antenna’s” wide open to learn from your mistakes .

What is the best Type of sander for a Beginner ?

The best sander for a total beginner carpenter and a person who isn’t so familiar with the sanding process , is a not very expensive orbital sander in the mechanical area and a couple of several grits sandpapers , in the manual area .

Should i sand in Circles or Straight lines ?

You should try to sand along and follow the wood’s grain to sand it , even if many carpenters like to sand in circles , or vertically or diagonally , or all these combined to the wood’s grain – fibers , for quickening reasons mostly .

There is no “forbitten” ways in wood sanding and if you don’t have your best priority not to disturb the wood’s fibers – structure , you can sand in al directions , you like .

Have as general “law” that sanding against – circle – vertical – diagonal a wooden surface , you sand faster and you “eat” wood’s flesh faster and in bigger dosages , but not smooth and mild .

What is the fastest way to sand wood ?

When you sand wood totally perpendicular or between the 45o and 90o degrees , to the wood’s fibers using much push – down force by hand , or using a very high speed in your sanders , you sand wood the fastest way possible .

Of course you’ll have smoothing – flattening and maybe design issues .

What speed should you sand wood at ?

Anything between the 8000rpm – 10000rpm , for your sanders will be just fine , in order to remove wood as effective as possible and with no unnecessary roughing problems .

What are some common Mistakes , people make when sanding ?

1) Don’t have clear “icon” of how much should they sand .

2) Neglect – “forget” , the face mask – eyeglasses , gloves , safety requirememnts .

3) Using inappropriate grit sandpapers , for the job .

4) Proceed too fast and not progressivelly to their sanding actions .

5) Don’t make enough progress checks , till it’s too late .

6) Sand “dirty” wood from previous coatings , et.c .

7) Sand wet wood .

8) Sand “against” wood grain( diagonal – vertical – circle , et.c ) .

9) Sand too much – sand too little – too much in central areas , “destroying” flatness .

10) Don’t change the exact moment their sandpapers – abrasives , with “fresh” ones .

How do i know if i sanded enough ?

If you want to check smoothness , touch your wood and feel it in every single inch , to identify if it’s in the smooth level you desire .

If you want to check its flatness and the uniformity you’ve given to the surface , use your eyesight and check it by angle in the light , changing the angle continuously , trying to find imperfections .

You can also use a winding stick or a straightedge to make more checkings in all of the possible range of possible micrometric problems .

You can supply some of the best straightedges and sticks from the markets for your checks , in HERE .

Should you wet wood Between sanding ?

No , you shouldn’t wet wood between the sanding process , because you’ll change the mass of the wood’s fibers , you’ll have expansions , changes of the wood’s “behavior” while sanding and for sure changes of your sanding’s progressiveness speed .

How much wood , can i sand off ?

You should sand the exact appropriate wood “flesh” your woodworking design requires , in order to have the desirable smoothness and flattness and follow the primary plan .

In any case you should be aware that we sand a wooden surface to make it smooth and flat and mostly we trim the surface , even if sometimes we sand a little bit more than usual .

We don’t get in the planing “fields” and space . If we want to sand very much of our wooden surface , it’s wiser to do it with our handplanes , out thickness planers , et.c and then proceed to our sanding .

I’ve gathered in HERE , some of my best and favorite planers you can buy from the markets .

What happens if you sand wood , too much ?

If you over – sand wood for any reason , you may have flatten issues , general twistings and bad uniformity of the wooden surface in general . You may harm the general straighness of our surface , and affect the thickness of it , badly .

In many cases you may need to pass it again from your power jointer , thickness planer from the total beginning , in order to do the process again and this time , correctly .

What can i use instead of sandpaper ?

You can use several abrasive pads and sponges you can find in the markets in a big variety of grits and some steel wood to make smaller adjustments and “cleanings” during your sanding .

Can i Clean wood with Water , after sanding ?

Yes , you can use water after your sanding is completely finished and this will help you see if you did a good job and maybe if any correction is needed .

You can use a simple cloth or a towel or a common sponge we all have in our kitchens , et.c .

If you want to use bigger amounts of water , maybe a hose or something like that , to clean perfectly the wood dust you should wipe the excess of water and don’t leave it on wood .

You don’t want the wood to soak water very much . You’ll have expansions .

What happens , if sanded wood gets Wet ?

If your finished wooden surface gets wet for any reason or by a weather change , you won’t have any issue and you should not be afraid that this will harm your previous sanding .

Clean and suck the water with a cloth , in order to protect your wood from soaking big amounts of water and have big expansion themes , let it dry and you’ll see that your surface is unharmed .

Of course protect it from hits and stuff like that , when its wet and its fibers are more vulnerable to get injured .

How do you Treat freshly sanded wood ?

You may treat your freshly sanded wood , depending on the use and the circustances of the future “life” this wood piece , will have .

The treating ways , methods , materials and combinations are “countless” for the indoor and the outdoor wood .

If you need wood treat for indoor use oils and waxes in order to be more heatlh friendly .

If you need wood treat for the outdoors , you can use dyes , stains , paint , several varnishes , polyurethane , acrylic paints , et.c and many combinations of them .

See in HERE , my top wood dyes suggestions to buy for your outdoor protection .

Is it Ok to sand wood , without a mask ?

No , it’s not ok and you must always wear the appropriate face mask with the correct and appropriate filters for wood dust , to protect your respiratory system .

A dust collector system is a must of course when you sand indoors and this is an unbreakable law .

The wood dust and the formaldehyde is extremely highly toxic and cause cancer according to the :

1) Agency for Research on cancer . ( IARC )

2) National cancer Institute . ( NCI )

3) Occupational Safety and Health Administration . ( OSHA )

4) National Institute of Health . ( NIH )

5) Canadian Centre for Occupational Health and Safety .

6) Goverment of Alberta . ( can cause Dermatitis )

Safety comes always first .

What are the side effects of sanding wood , without a mask ?

You may suffer from sneezing , allergies and bad coughs , dermatitis according to the Alberta Goverment , to very – very serious respiratory problems and general health issues and even death , if you don’t use your appropriate face mask and safety gear .

I’ve seen retired carpeners with half of their noses and parts of their faces missing from many surgeries , caused from inhaling wood dust .

I’ve seen and heard many carpenter cases , of losing even their lives from wood dust .

Always put , yours and your surroundings safety first .

Is breathing sanding dust , Bad ?

Yes , it’s extrememly very bad and you should protect yourself , by wearing the correct and appropriate face mask , which is focused and made to filter the very tiny wood dust .

See above what the best world institutes say for the wood dust and formaldehyde ( MDF’s et.c ) , say and their connections with cancer and more health issues .

Can i sand wood Indoors ?

Yes , you can sand wood indoors , only if you’re wearing the correct face mask having the appropriate filters for the tiny wood dust and have a very good – the best you can have , dust collector sustem .

These two safety measures combined . If you don’t have a dust collector system , be very carefull with your face mask and its filters , to be always “fresh” and have all the windows open to have airflow .

If you can avoid the indoor sanding if you don’t have a dust collector system , do it .

Try to do it outdoors .

I know and understand that most of the professional carpentries are indoor places , but in these cases , you should always have the best possible dust collector system . No “discounts” in here .

Wood dust can cause cancer and many – many other health problems .

Is wood dust Bad for the Skin ?

Yes , it’s certainly bad for the human’s skin and can cause from dermatitis and serious allergies ( especially if you’re sensitive to allergies ) , to extremely serious health problems as cancer , et.c .

Remember that our skin “breaths” too , not only our lungs from our nose path .

Put always your safety first .

Keep woodworking and gain the best of soul happiness .