You’ve done the old finish removal from your wooden projects .

Your surfaces are 100% clean from anything old and you want to smoothen your wooden surfaces to proceed to your oils and waxes-varnish-shellac-lacquer-polyurethane-paints and whatever finishing you want .

The sandpapers , abrasives and steel wool are the appropriate woodworking equipment you need in here to finally finish – smooth your wooden surface .

Their “mission” , along with the wood’s sanding with your other tools ( orbital sanders , belts , et.c) , is to correctly prepare the wood’s surface for the final finishing , with your oils , waxes , paint , et.c .

Woodworking is Freedom & Emotions first of all .

Let me say this in here : “In woodworking every carpenter does what he wants to do and what he likes and he can bent the written and unwritten carpentry laws ” .

All this smoothing-sanding-finishing equipment is necessary and “welcomed” to help you smoothing , sanding and finishing your wood plans , you have the freedom to do what else you like in any case .

Personally in many cases i don’t want-like to smoothen totally my wooden surfaces .

I want the wood’s pores to be open , in order to “suck” more linseed oil and after the drying i do the smoothen process or i don’t smoothen at all .

In many cases and wood types , i like the rough feeling in my arms , so i let me wood stick – desk , et.c , to be rough . I wanted to clarify this . Be free to experiment and do what you like and want .

Sanpapers & Abrasives are “must” .

You may do the smoothing job , by using only your scraper card and planers and for many , they’re the best wood surface smoothing carpentry equipment outhere .

Yes if you “deal” with a “perfect” wood piece , your plane’s adjustment and blade sharpening are perfect , the smoothing result is totally perfect and need no more .

But if you have a difficult surface ( curved-antique , “strange”design , et.c ) , the sandpapers and abrasives are needed .

I like when i want to totally open the wood’s pores in order my linseed oil to penetrate the deeper possible .

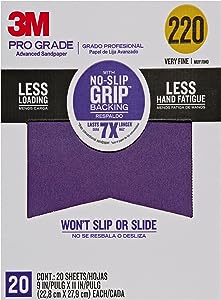

There are “millions” of sandpapers , types , brands , varieties , et.c , but my favorite sandpaper brands are first of all the 3M and the Black & Decker .

You know you’ll may( and me of course) test many sandpapers , but you’ll always return to the 3M .

This 3M 220 grit package , is a very fine and good’s quality of sandpaper , it holds its sharpness longer than you may thing and it’s very durable . Check more and the price on Amazon here .

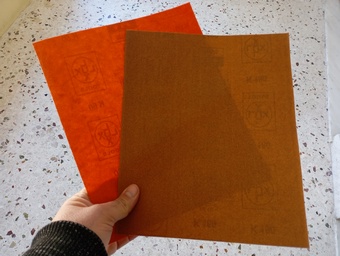

If you want a more basic series sandpaper , but always from the 3M check this garnet one . It may be more cheaper than the above , but it won’t tear apart in a “glimpse” and you won’t need “tons” of sheets to do your job .

Make your purchase on Amazon in here .

Black & Decker is also a very nice sandpaper brand and this aluminum oxide grain piece is very capable , will last long enough and will do the job , just fine . Check more on Amazon in here .

The 3M brand is “dominating” to the abrasive pads fielad also and this grey 3M Hand Sanding Wood Finishing Pad , is fine example of the brand’s quality . It may look like your kitchen’s dishes pad , but it wotks with wood very good .

Go and get it on Amazon in here .

It’s super easy to work with and if you combine it with a finishing oil , you can do amazing finishes , even to extremely elite woodworking creations : musical instruments , antiques , et.c .

** Remember the grit range of the 3M colors : green=100grit , grey= 280 grit , white=600 grit .

Extra TIP : The common Scotch Brite pads we all use in our houses , are made frm plastic matierials which is great for finishing-sanding a wooden surface !!!! There’re tough enough and they leave ZERO fibers behind them .

Try to have heavy-duty ones as these ones from Amazon here .

Finally you should have some good’s quality(but not expensive) steel wood to make the final finishing of your wooden pieces .

You can also make some corrections between the finish layers and sand to difficult places of your antiques , “strange” surfaces , et.c . Of course you don’t apply wood finishing with steel wool .

The use of #00 or #000 and #0000 steel wool will give the grit range from 300 grit to 500/600 grit for your final finishing .

ATTENTION : if you use a water-based finish , you should be aware that you’ll have some rust themes with your steel wool .

The same applies for this HOMAX Number 00 Steel Wool Pad, Gray , which costs 5$ bucks and can do jobs from gun metals to wood finishing and more .

Check more on Amazon here .

Your scraping sanding , smoothing and cleaning your wood’s surface is over , but your entire finishing job isn’t !!!!!

Wood fillers , wax sticks and grain fillers are needed for sure to do a correct and complete job .

Keep woodworking and always smile .