When you are a total beginner to a new area/field is very common to have fears and the same maybe happens to you , concerning the woodworking area .

In order to tell you the basics for your entry to this so “magical” hobby the woodworking , i should underline you that , don’t be “be afraid” to make mistakes ( everybody does ) and never forget your safety measures .

I’ve written a complete article for this and if you have time , read it in here .

If you have zero woodworking experience and knowledge , don’t worry .

1) Learn as much as you can , the Nature , the Properties and the Interaction the wood has , with the environment .

Wood is the primary and basic material of the woodworking activity and you should try to get knowledge for it and its “behavior” , while you are acting with it .

Wood is an “alive” material and it changes every single moment , affected by the physical environment and the actions( interacts with you ) of the carpenters above it .

So , it’s very crucial for you , to learn as much as you can for wood , in order to proceed to the next steps of the woodworking activity .

I have a complete post for the properties , the errors and the enemies of wood , with a couple of helpful videos you can see in here .

2) Have a personal Place to work with wood with safety – calmness – focus – accuracy .

After the knowledge you’ll get for wood , a peacefull place to make your first creations would be ideal . This doesn’t need to be something “extreme” and professional .

A small area in your house ( even if you live in an apartment ) , in which you can have a small table and some shelves/places for your woodworking tools , can “do the job” just fine .

Tip : In order not to bent much and have back pain( lower back mostly ) , your table or woodworking bench’s height should be in the height of your belly button , more or less .

3) Buy Gloves and a very good’s quality face Mask , for small injuries protection and wood dust .

The gloves will protect your hands from wood spikes during your cuts and wood actions and the very good quality’s face mask wil protect your lungs , from the wood dust molecules .

These molecules are extremely tiny , they go to your lungs through breathing and the damage is big .

Your safety comes first , always .

4) Begin your 1st Woodworking Tool Supplies & Learn how to use/maintenance them , with efficiency and safety .

Now it’s time to supply your first woodworking tools , in order to cut – drill – join – shape – smoothen – finish and protect your first woodworking project .

If you want to remember the list of what tools you should have , as an amateur woodworker , read THIS article .

Don’t worry if in your first steps you’re making mistakes using your tools . We all made mistakes and if you’re blessed to have a more experienced carpenter to show to you some “stuff” , even better .

Practice as much as you can , make mistakes , learn from them and the most important : Keep trying .

In this way , you’ll learn the exact and correct use of every single wood tool .

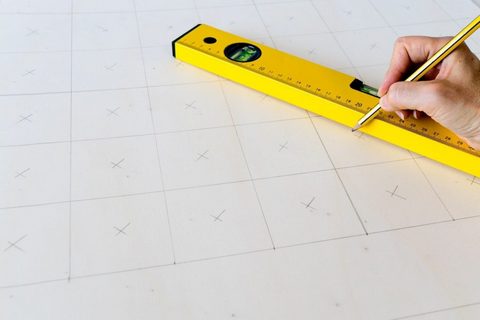

Tip for Correct measuring :

According your place to live the metric systems are changing .

Some continents/countries use Cm. ( centimeters ) , other inches , other pounds , other kilos , et.c . That’s why you’ll see the tape measures have many numbers , above them .

They are manufactured , to adapt to all earth places . The same applies for the weight of the hammers , axes , et.c . So be carefull while you’re measuring wood distances .

5) Visualize in the 3 – D dimensions space your woodworking plan , Design it on paper , and Proceed to make it Real .

This is maybe the most demanding phase for you . You’ll need to visualize the woodworking project you want to built , in the 3 – D dimensions space , in order not to be awry , then put these thought on paper and move on to create it .

This phase is the most crusial maybe , but it isn’t very difficult as it may seems to be .

Your first design attempts won’t finish first in a design contest , but as the times passes you’ll make design corrections and everything will go well .

It’s very important in here to take your time , not hurry , so your complete wood design be as perfect as possible .

Why ?

Because this wood design will be your basic column , to start and finish your wood plan with perfection .

6) Your Wood Design is ready , it’s time to supply your Wood .

Without wood you can do nothing , so it’s time to make your first wood supplies . These can be in a primary level , from you directly from the forest ( always with the appropriate forestry licences ) , or from the nearest wood shop .

Always try to choose the best wood quality for your projects . In the first case ( cut it directly from nature ) , you cannot do much for the wood quality .

You saw your wood , you cut it , you bring it to your warehouse and you’re starting to shaping it .

If it has some problems , you’ll do your best to fix this themes , but when you buy wood ( logs – boards – entire trunks , et.c ) from a store , try to choose the best possible .

See the color of the wood , its texture , its straightness if you buy boards , signs of maybe bug problems ( even the tiny ones are sign of a “sick” tree ) , its general good health .

Ask questions to the salesman and judge your own .

7) Now it’s time for Measuring – Cutting – Joining and completion of your Wood Plan .

If wood is the basic column of the carpentry activity , the correct measuring is for sure another one basic column .

If you measure incorrect and not according to your woodworking plan you designed earlier , you’ll cut incorrect , you’ll join wood incorrect and your wood plan won’t be good at the end .

Measure your wood distances and lengths with “surgical” accuracy , use a very well sharped woodworking carpenters pencil to mark with the same focused accuracy and only then go to the cutting step .

HERE are my top pencil and lead holders products to buy and have for your precise marking .

Take your time , double and triple check your measures and marking points and only then go to the cutting wood process .

Why is that ?

Because , once you cut wrong you cannot go back and fix it . When you cut wood , the cutting is permanent . So in here be 100% focused , not to make any mistake .

Yes , of course if you make a mistake and you cut longer than you should , you can fix it and cut again . But if you cut shorter and awry ?

You cannot do anything .

Don’t be afraid of the calcualtions and maths you may need . The basic maths a carpenter needs for his beginning are these .

You measured , you cut , proceed to put together your wooden surfaces and complete your plan .

At the beginning , some nails , screws and some wooden glue will be well enough for your wood joins . As you become more experienced you’ll learn more joining technics .

8) You’re ready . Make some Smoothening and Protect it with some finishing oil , or other preservatives .

That’s it . You’ve finished . Your first wooden chair , desk , table , et.c is ready . Don’t forget to make your sanding actions on it , to make it perfect and be sure that no wood spike , to harm you exists .

Use your planes , rasps , sandpaper or sponges( they are easier ) and make it smooth in all of its surface , even in the tiny ones , or the ones are kind of hidden form the eyesight .

I’ve chosen some top abrasives – sandpaper , et.c , products , to prepare you wood in HERE .

Last but for sure it’s not least , don’t neglect to protect your creation , with a nice quality’s finishing oil .

The “old days” woodworkers used fat from the animals . Some carpenters nowdays , like this and use it also , but in the markets you can find very good finishing oils . Choose what you like the most .

If you want wood finishing using the less possible chemicals , go and see these products i have in HERE .

Wood is an “alive” material and the weather conditions , can harm wood badly , if you let it unprotected . Wood has many enemies and moisture , fluids , chemicals , bugs , the hot sun and many other are some of them .

The finishing oil is built to protect it from these factors and you should never “forget” to paint your wood with it .

Of course you can protect your wood plan with many more preservatives than oils and waxes .

If you want the best stains-varnishes-water based varnishes , et.c my top suggestions are HERE .

TIP : Never Neglect – Postpone , the Maintenance of your tools .

When it comes to the maintenance of the woodworking tools , many woodworkers( me included ) make the mistake to neglect and postpone , the correct maintenance of them .

If you want your wood tools to last for a long time , i suggest you , not to do that .

What you should do for the proper and correct maintenance of them ?

Always follow the official manufacturer instructions and read this post , for more clarification .

For your first wooden projects and you “early days” , in the wood “planet” , you won’t need something more sophisticated .

You don’t need , high tech metric tools or being a master on wood joining , wood identification and the whole knowledge of the world .

Simple and basic approach , some nails and glue and when you become more exprerienced you’ll do more and more and more .

Happy Woodworking .