During the creation of your woodworking plans you’ll need for sure many tool “helpers” and carpentry machinery , in order to be able to finish the “job” . The several type of clamps are for sure some of the more serious auxiliary woodwokring helpers .

These auxiliary tools , aren’t giving only “auxiliary help” , but they are very important for any woodworker , amateur or not . Especially if you’re working alone in your carpentry warehouse and you don’t have any external help , these tools are precious the most .

The woodworking clamps are wooden – plastic – metalic auxiliary tools which have the claw holding – tightening – stabilizing approach – appearance – “philosophy” and we use them , to hold or press or stabilize our wooden projects or parts , in order to proceed to our next carpentry steps .

The clamps are basic woodworking auxiliary tools , we use to stabilize – connect – press – keep wood pieces together( temporary ) , during our woodworking creation process .

These tools are helping us when we make small or bigger design adjustments , by holding our entire project in one piece , so we can be “free” to make corrections , final adjustments , et.c .

If you like to remember the list with the 10 basic woodworking hand tools , go in HERE .

How many Clamp Types exist and How do i choose them ?

There are many types of clamps in the markets ( more than 20 – 25 types ) , because the woodworking activity has a huge variety of designs and as you can imagine , many different wood pieces concerning their shapes , lengths , widths , et.c .

That’s why you should have as many clamp types you can , in order to be “spherical covered” and be able to stabilize – keep together , whatever wood shape you’ll find in your carpentry activity .

The best approach to make correct and helpful clamp choices , is to go slowly – slowly in your clamp purchases and to make different material combinations .

Sometimes you’ll need “stronger”clamps from metal , sometimes you’ll need plastic clamps and sometimes you’ll need both to keep your project together .

Begin to buy clamps “driven” by your project needs and don’t be stressed if you cannot have them all . You’ll use some clamps very rare and other types of them , will be your daily assistants .

These are all the Basic clamp types :

1) Wooden Hand Screw Clamps .

These are very “traditional clamps and they don’t “hurt” the wood pieces . They’re created by two long and separate wooden pieces ( like jaws ) , which are coming together with screw handles . They are very useful and you can hold even very small pieces of wood .

2) Parallel Clamps .

They are maybe the most “popular” woodworking clamps . They can give you “deep” clamping power and their “jaws” are moving parallel , which gives you the benefit of equal clamping force to all the wood pressure .

There are very versatile and you can complete the majority of your clamping “missions” .

3) The F – type Clamp .

These have the clamping “approach” , of the parallel clamps , but with a major difference . Their pressuring holding force isn’t equal to all the wood’s surface , but it’s “focused” in a specific spot .

Because of this targeted pressure , try to buy F – type clamps having in their pads a plastic topping , in order not to leave marks( from pressure) on your wooden surface . They “grip” very strong .

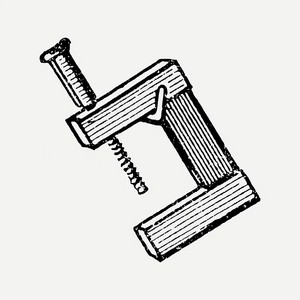

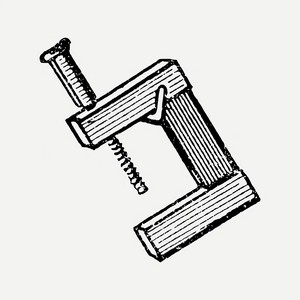

4) The C – type Clamps .

These are small clamps( 4”-8”) and very helpful when you gluing your wood , especially wooden boards . They’re very versatile and they have the pressuring approach of the F – type of clamps . They give targeted clamping pressure .

You’ll have many of them and you’ll use them very often for many carpentry “missions” .

5) The Racheting Clamps .

These are mostly for applying your glue to your project and their holding force isn’t very big , but they have a very big advantage . They have a quick release button and this is very helpful .

They’re like the F – type , but they’re made from plastic and they have rubber or soft silicone in their pads , so you can “grab” elegant and expensive wood with them .

6) The Spring Clamps .

These are like the clothespins , we all have in our houses for our laundry . They have enough power for their sizes and they used mostly for smaller detailed woodworking jobs , gluing , et.c .

7) The Pipe Clamps .

When you won’t be able to use your parallel clamps because your wood piece is bigger , you’ll use these type of clamps .

Of course there are many other clamp types as the miter joint clamps , strap clamps , workbench clamps , quick grip clamps , heavy duty ones , et.c , for any holding and connection purposes a carpenter can imagine .

A workbench Vice is “must” and the “King” of holding . See my top suggestions in HERE .

What should i Avoid and know , when i use my clamps ?

Keeping two wood pieces together using clamps may sound an easy job , but it isn’t . If you don’t want to ruin a nice carpentry project at its final stages , you should use the pressuring power of your clamps , with cautious .

Always proceed slowly – slowly when you’re screwing your clamps , or “grabing” . You don’t want to put awry pressure on your wood pieces , because the result will be awry , too .

Especially when you gluing , your wood pieces will be “slippery” from glue . You need to screw – “connect” very slowly , carefully and continuous check the straightness and verticality of your project .

A very significant situation you must always avoid and be very careful , is to never use your power tools – machines( ribbons , et.c ) to a piece of furniture , you have clamps on it . The danger to hurt yourself is way too big .

I’ve written a post of how you can nail a pin near a wooden board’s edge , without ripping the wood , read it in HERE .

Keep Woodworking .