A carpenter no matter if he’s(or she’s) an amateur or a professional , he acts with wood pieces in order to create his woodworking projects and having a vice to help him , is crucial .

Most of the times he doesn’t have only one vice but many of them .

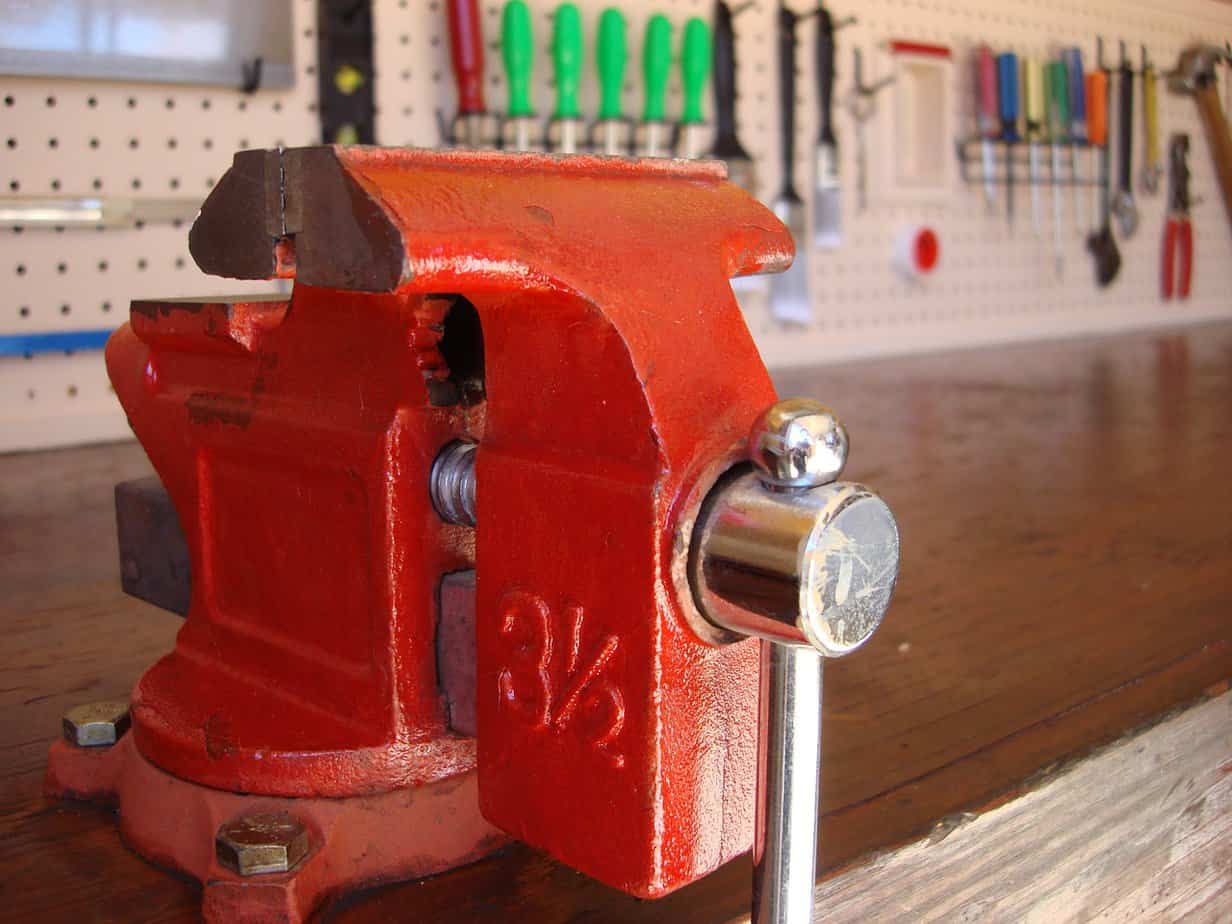

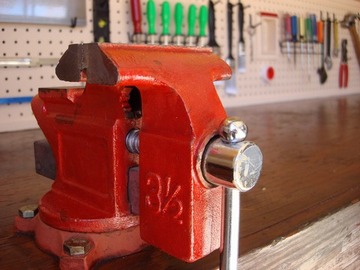

The carpenter’s vice is the metalic or wooden woodworking tool attached to a workbench , which has two “jaws” that are open and close using a screw movement style and holds the wood piece still and firm , so the carpenter act on it ( plane , cut , sand , drill , etc ) .

See my favorite vice suggestions and some choice “secrets” , in HERE .

You need to have many types of vices on your workbench , because you’ll be working with several types of wood pieces , having different shapes : lengths , widths , surfaces( curved , arcs , edged , etc ) and all these should be restrained still and firm , in order to work with them .

Most of the vices you’ll need in your woodworking activities , will be attached to your workbench primarily in its faces and its ends , but you’ll need to have a good quality metalic vice , for more heavy-duty jobs .

Attention in here : You should ALWAYS have two wood pieces attached to your vice’s “jaws” ( as a protecting shield ) when you work with wood , otherwise you’ll damage permanently the wooden surface while squeezing it , in order to be steady .

What Size of a Vice , do i need for Woodworking ?

The extra metalic vice you’ll get from the stores and want to add to your workbench have a big variety of sizes , but have in mind that the biggest and more heavy-duty ones have : 16″x7″x9″( L x W x H ) , 4″-8″ for jaw width , 4″-7″ for jaw opening and clamping force between 3000lbs – 7500lbs .

Of course you cannot relay only on one type of a vice and this extra metalic vice is coming to complete the several vices , your workbench has .

What are the different Types of Vices ?

Your woodworking bench , primarily will have many vices attached on its bench top which we can seperate them into two big categories :

1) The Face Vices .

These are the vices that you see in the front and back surface-face of the workbench and point towards to you .

2) The End Vices .

These are the vices which are attached to the two ends of the workbench .

More specific the woodworking vices you’ll met in your bench are :

a) The Leg vice : You find it more in the antique benches and it’s attached to the front leg and tighten with a handle screw movement .

b) The Tail Vice : It has a bench “jaw” and it clamps your wooden piece along to your bench top .

c) The Face Vice : It has the same thickness to your bench top , it has a longer “jaw” and clamps your wooden board with two screws .

If you have a very wide board , these two screws , will be a theme and won’t allow the “jaw” to grab the board , very equal .

d) The Shoulder Vice : It’s maybe the most lovable vice , because it has an unhintered opening and allows you to do wood jobs on very wide boards .

e) The Cast Iron Vice : They’re attached-screwed to the down side of your bench top and you should always use wooden “shield” to grab your wood .

f) Auxuliary Vices : You can attach it wherever you like and they’re two long pieces of wooden boards that they tighten with twoalso wooden screws . They’re very comfartable for dovetail making . You can also hear them as the “Moxon Vices” , from their founder Joseph Moxon .

g) The Wagon Vice : It has the same approach as the tail vice , but instead of using a screwing “jaw” to hold the wood , we tighten wood with another similar way .

From a bench top scarf , a bench dog unveils and you adjust it to tighten your piece .

h) The End Vice : It’s attached to the end of the bench top , has the same length as the width of the bench top and you can tighten big wooden boards-pieces between the screws .

It’s like the face vice , but at the end of the bench .

These several types of your workbench vices have several sizes . Some are wider some , some are shorter so you can have comfort when you tight your different sizes of wood .

The woodworking vices are made from metal ( cast iron , etc ) or are made from wood .

What Kind of Wood do you use in a Wooden Vice ?

Usually the wooden vices you’ll find in the stores or your workbench have on it , primarily are made from maple , but this isn’t an unbroken law .

The wood of a vice should be from the hardest types of wood , for many reasons . A hard type of wood made vice , is more easily manufactured even in a small detailed scale .

It also can be attached to your bench more tight and not having breaking problems during the process . A strong hard wood made vice , gives more sturdiness on heavy-duty jobs , it can tighten better and more “surgical” small wood pieces , “hold the tightening” better and of course have better feeeling .

If you want to reminder concerning the types of wood , go in HERE .

How do i choose a Workbench Vise ?

The correct and wise buying mentality in here is , that you want the appropriate vice for the specific woodworking jobs you’re usually making and all this combined with the amount of money you have and the best possible quality you can get .

If you create only small carpentry projects ( small sculptures , miniatures , etc ) you don’t need to have the biggest vice on the markets .

You don’t need a heavy-duty vice . You need a smaller one , but for sure very well manufactured . You need precision , detailed “sweet” tightening and not harming the wood piece , a nice pressure “holding” and a smooth jaw movement .

You don’t need a heavy – duty clamping force and extraordinary power in here , but more artistic approach made .

On the contrary , if your woodworking projects are more big , heavy-duty , you’ll need other vice priorities for your “missions” . You should go and purchase the most strong clamping vice you can get , but having also the best possible quality and smoothness .

If you’re doing a mixture of wood jobs , a medium scale vice will do the job . Always have in mind that your carpentry needs is the “lighthouse” for your vice purchase .

Keep woodworking and be happy .