The wood furfurylation is a very new wood improvement technology and it developed and started back in the beginning of the 2000 in the Norway . In our days and with our very big needs for wood , the tropical and the other kind of expensive wood , isn’t enough anymore .

The planet cannot supply us with the quantities we need and the wood is a major material for many of the people’s needs .

So we needed ways to make the cheaper and more “common” wood , better and with advanced properties . For sure the impregnation makes wood more resistand to hard conditions , but many people want their wood to be totally green and with zero chemicals .

If you like to remember the impregnation method , read in HERE .

Is Wood Furfurylation totally Green ?

The wood furfurylation comes to fill this eco – friendly “gap” . It’s a totally green method to give you wood advanced properties . In here the process uses zero chemicals and it’s totally eco – friendly , so you can be certain that the result will be 100% ecological .

See some best wood protection solutions to buy , without using strong chemicals in HERE .

This eco process also , upgrades your wood to be a “class 1” wood , equal to the teak wood and other tropical durable species .

What is the wood Furfurylation process ?

1) In a chamber we put inside the timber we want to modify . This timber can be whatever we want , but usually is the cheapest kinds of wood and not the expensive – “luxury” ones . See in HERE some expensive types of wood .

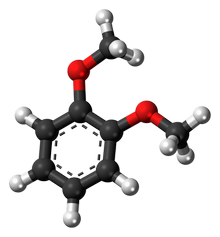

2) After the first step , we ingrain the wood’s mass with a totally green element which is called furfuryl alcohol . This alcohol swells inside the wood’s cells , getting them ready for the next step .

3) In this step we heat the chamber ( more than 1000 C ) and this heat polymerize the furfuryl alcohol and makes it more advanced and strong as we want , but we aren’t finished yet .

4) The last step is the drying process of the entire wood’s mass and balance its moisture to the level we want ( 10% – 12% ) .

That’s it , we finished . Now we can take our modified wood , havind the appropriate properties we wanted .

This process looks like the heat treatment wood process , you can read in HERE and they both are very nice wood strengthen methods .

What are the Advantages of the wood Furfurylation method ?

1) It’s a totally green method . The furfuryl alcohol is a plant residue and it isn’t made in laboratories , using chemicals , et.c .

2) Our final product , the wood is way more advanced from its original form . We take “class 1 “ wood , after all this .

3) The wood becomes more strong and resistant to bending and percussion .

4) Our final product is totally green and eco – friendly for all the uses we like . For indoor – outdoor furniture and won’t affect our health( allergies , et.c ) in any way .

5) The wood has more and higher aesthetic value . It’ll look way more expensive and with higher prestige , of course .

6) The wood will have way better dimensional stability , in all the weather and other conditions .

7) It will require way less maintenance and if you combine this process with eco – friendly maintenance methods , your result wil be magnificent .

See in HERE my favorite wood maintenance mentality and “secrets” , using green products .

8) The wood’s lifetime , will be extended very much and with less problems .

9) The wood will be more resistant to moisture and hard wet conditions( boats , pools , et.c ) will be better .

10 ) This kind of wood has way better “behavior” with the fasteners of all types . Stronger wood , stronger wood connections .

11) Its energy footprint , is almost zero !!!!!

12) It’s a very easy wood to work with , with hand tools or with power ones .

Where can you use the wood Furfurylation modified wood ?

This strengthen wood is used wherever you want strength and resistance , under tough conditions .

You can trust it to : marines , boats , pools , outdoor constructions , in gardening , on bridges , on yacht decking and on decking in general , of course for your indoors wooden furniture , in hotels , et.c .

Is it a cheap or expensive process ?

As all the procedures that require to go to the professionals and use their chambers – ovens or whatever , you need to spend some money , but it isn’t a highly expensive process .

For sure the result will justify you , because you’ll take a way better timber , equal to the most expensive ones .

You can supply cheap wood and make it better in a very high level and maybe the most important . A very beautiful aesthetically wood . For sure it worths consider it .

Keep woodworking and gain happiness from it .