One of the most difficult woodworking “missions” is the correct choice of the wood you want to use for the outdoor conditions , in order not to have failures and the wood last a long time .

The outdoor conditions are way more complex and difficult than the indoor ones , for all materials and not only wood .

It’s way more easy to create a Formula 1 tιre , than a car tιre for the daily needs of us , the regular people and our regular cars . The Formula 1 tire will have to deal with specific conditions and for only a couple of hours , than the regular car tire .

The regular car tire should perform generally very good , for a couple of years and in a “million” of road and other conditions , during its lifetime .

This is a very difficult “puzzle” . The same applies to the outdoor wood .

The combinations of the conditions are too many and the stamina the wood should have should be big .

I’ll share with you a guidebook to choose the best wood for your outdoors , from my experience and the expert knowledge i shared with a Greek Professor in our University for the wood technology , in the northern Greece .

If you want the complete wood guidebook , for all the wood uses and not only the outdoor , go to my past post i made , in HERE .

Before all , you should be aware of a thing this grandmaster University Professor told me once :

” Sometimes when you’re dealing with Green elements as wood , the percentage of failure is always present , no matter how many correct things you did or whatever . “

What wood is Best for outdoor use ?

What wood is the most Weather resistant ?

What is the Longest lasting outdoor wood ?

Can Any wood be used for outdoors ?

What is the Cheapest wood for outdoor use ?

What kind of wood Doesn’t rot outside ?

What wood is Waterproof best ?

What wood is resistant to Rain ?

What to put on wood , so it can Stay outside ?

Is Pine , ok for outdoor use ?

Is Plywood good , for outdoor use ?

Is Walnut wood , Weather resistant ?

Is Oak good for outdoor use ?

Is Oak wood waterproof ?

Best wood Types , Specialized for Outdoor use .( extended )

1) Industrial – Engineer wood .

All the industrial – engineer wood , that is technical made from humans , have way better resistance – stamina to the outdoor conditions and can last longer than the natural wood , with way less maintenance needs .

The industrial MDF , OSB , particle boards , and whatever else of wood “sandwiches” of wood along with resins , glues , acrylics , et.c , are designed into factories by humans and have very high and upgrade capabilities , the natural wood doesn’t have .

We want our wood to be way more tough than the natural species are and we just made it ourselves into factories , using chemicals , pressure , heat and whatever else .

The industrial wood is the best solution for outdoors , concerning the resistance , long lasting and with less maintenance from us , factors .

Of course it cannot reach the beautiness of the real natural wood .

If you want the best performance and wood toughness for outdoors , choose industrial wood .

2) Pakkawood and Marine Plywood .

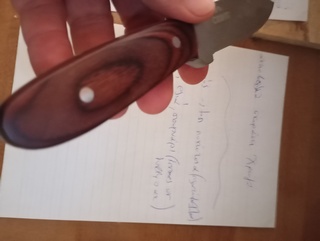

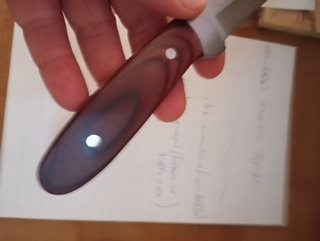

Pakkawood is industrial wood made from veneer and resins combined together with heat and pressure and it’s an extraordinary good wood choice .

Many Japanese – as they invent it – ( and not only ) wood chef knives have pakkawood handles and their resistance of this wood type is legendary .

I cannot agree more , because i have a couple of cheap and expensive knives with pakkawood handles and they’re great , as you see in my below photos .

Pakkawood can handle continuous abuse , water , fluids , hits , et.c , very – very easily with zero damage and i recommend it highly , for smaller( or not ) outdoor crafts and whatever else you like .

You can find it in reddish color in blue and whatever you like , as the resin can make it as you wish .

The marine plywood is the boards you see and step on , in the pools , in the showers , many times as an exterior decor in apartments or block of flats ( it’s very popular ) and in general in many outdoor woodcrafts .

It’s very resistant to moisture , water and outdoor conditions , that’s why it’s very expensive to buy . Yes , its price is high , but it worths it for sure .

3) Furfurylation – Acetylation – Impregnated – Shou sugi Ban – Heat process , wood for outdoors .

All these 5 wood processes you can make to natural wood , it makes it way stronger and resistant to the hard outdoor conditions and there are highly recommended .

The furfurylation process more extended is HERE , for you to see .

The acetylation process post with the whole process is HERE .

The impregantion of wood by using salts and other chemicals is maybe the most capable technical process and modification you can do to wood , in order to make it very strong and long lasting .

See the entire process with al the details in HERE .

The Shou sugi Ban process comes from the ancient times in Japan and in other areas ( i think the ancient Greeks did it also ) and it uses the fire , to make the exterior surface of wood , very strong .

You just burn( controlled ) – carbonize the exterior of wood and you make it extremely durable for a very long time .

See the exact process with videos in HERE .

It’s highly recommended , to the wood parts you want to put inside the soil for supporting or creating several woodcrafts , fences , et.c .

The heat process for the natural wood is another green way to make your wood stronger without the use of chemicals and it’s a fine method .

Of course it doesn’t make the wood so tough as the impregnation or the shou sugi ban technique , but you can use this kind of timber for your outdoor woodworking projects .

See the entire mentality and the process for the heat wood treatment in HERE .

Which wood for Outdoor Sheds – Pergolas – Kiosks ?

For these types of wood creations , you’ll need to use impregnated pines with salts , cedar wood , cypress and redwood ( sequoia ) .

Which wood for Outdoor Houses – Warehouses – Agricultural constructions ?

We use many types of pine ( white – black ) , cypress , Australian ash , Libanon cedar , many varieties of oak ( USA ) , red cedar , padauk and of course spruce , impregnated or not .

Which wood for Outdoor Fences – Doors ?

Cypress , acacia , impregnated pine or spruce , several places chestnut , cedar( mostly red ) , oak , impregnated birch and many types of tropical wood types which are tough and outdoor capable .

Which wood for Outdoor Railroad ?

In here except all the others , you’ll need extra strong mechanical durability for the wood you’ll choose and usually the trachea pine ( pinus blutia ) , azobe , Japanese oak , cedar , chestnut and pine cone wood , are the most suitable .

Which wood for Outdoor Bridges – general Decking ?

In here we need strong mechanical properties , along with resistance to salty conditions if we talk for the decking area and the correct wood choice is super serious .

The black pine , the impreganted pine , the azobe – greenheart – opepe – iroko – wenge , teak and some other tropical wood , the British oak , the cypress and the US cedar are some of the most capable wood choices .

Which wood for Outdoor flooring ?

In here the tropical wood is the big winner concerning the big use of it , in this type of outdoor woodcrafts .

The Brazilian cherry , the iroko , the padauk , the wenge , the azobe , along with some several types of oak and cedar , are the most popylar wood types .

The black pine can be used and if you use impregnation , you can use more pine species .

Which wood for Outdoor Playgrounds ?

The most common timber in here is the impregnated wood with borate and other salts , either pine and spruce and the cypress and iroko .

** The Bamboo wood is a very capable type of wood , to use outdoors , for roofs , for wind – airflow control , for dust winds control , to create shadow for an area , to create a light private place in your garden and for generic fences .

It’s super light , it needs zero maintenance and it’s very strong and resistant to all the variety of weather conditions , in your conuntry – place .

It only gets more grey from the sun’s UVs . It’s a very nice and cheap outdoor choice .

Extra Information for your Outdoor wood .

1) The outdoor radiation will darken your wood’s color a little , no matter what you’ll do to protect it , but it’s not a big deal , as you see in this log house photos .

It’s the same outdoor wall , after a couple of months in the sun’s UVs .

2) The moisture of wood when it’s in the outdoors and it’s physically balanced with the environment , is always less than 30% .

Your outdoor wood should be in the 18% – 22% moisture area generally and in the 13% – 17% moisture area , if we’re talking for outdoor covered wood .

If we dry our wood naturally , using the air flow we bring it around the 12% – 15% moisture area .

3) The hardwood types are more outdoor capable wood choices , because they have bigger density in their masses and the density is an extremely significant factor , for the outdoor wood .

The bigger the density , the better .

A bigger density wood , has more thick molecules and this means better mechanical properties and strength .

Cypress , Olive oil tree , mulberry wood ( if you can have wild one , the better ) , alder and yew wood , are some of the best wood types for your outdoors .

Always check these quality factors for your outdoor wood .

Your outdoor wood should have high “score” in the areas of :

1) Density .

2) Percussion .

3) Bending .

4) Twistings .

5) Traction .

6) Compressive strength under angle .

7) Resistance to weather properties generally .

8) Resistance to fatique .

9) Resistance to creeping .

We have a ancient Greek word for the creeping it cannot be translated to English , accurate .

What is creeping ?

Creeping is the strength ability your outdoor wood should have to a continuous external power , applied to a specific spot of the wood , for a long time .

It’s very close and similar to the fatigue factor and the general strength of wood , to continuous strengths applying .

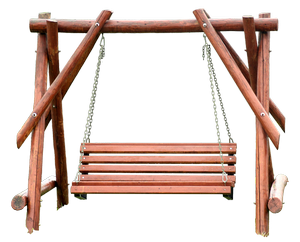

If you want to create an outdoor swing for your kids( and not only ) , the horizontal wood log in which you’ll “hung” the swing’s seat with chains , will “accept” high powers in the 2 spots you’ll attach the chains , to place the seat .

These “hunging” powers will be continuous and big . The log should be strong enough and have the appropriate durability in these 2 spots .

This is called the creeping durability and stamina of wood for specific small areas under continuous big powers and it’s very crucial .

If you create an outdoor bridge , the logs you’ll use to support as props to the whole structure , should be able to endure the weight and this weight will be continuous , for specific smaller spots .

Outdoor wood choices , if you don’t have Money .

If you don’t have enough money to get some marine plywood , or a very good and top hardwood or an industrial wood or an impregnated one , et.c , you can do this as i did and do many times :

1) Get whatever wood type and piece you can and try to make it strong and long lasting with the variety of the natural – chemical finishings in the markets and the combination of these two “worlds” .

I have a very cool post for this in HERE .

2) Get your wood , buy some linseed oil to use as an substrate which is super cheap ( 5$ – 7$ the liter ) , soak your wood in it , let it dry and then finish with an impregnation polyurethane .

If you want color use an oil based paint , to match it with the oil .

The beekepers use oil to boil their hives and then a couple of oil based paints and their hives last for many – many years . Do the same .

When your oil paint will start to fade from the sun , et.c , the linseed oil( or whatever oil ) will make it fresh again , moisturizing it .

My top linseed oil suggestions in HERE .

3) Never use a crust making finishing . The crust surface will crack eventually , leaving the wood unprotected .

4) You can use only a decking oil , which is super tough and spend no more .

5) You can use only a teak oil for bugs – fungi protection , along with the oil benefits .

6) If you’ll “sink” some parts of your wood into soil( for a shelter , et.c ) , use the Shou sugi ban to carbonize these parts and protect them .

Having a very small amount of money , shouldn’t stop you from protecting your outdoor wood .

You know the old days when people was very poor , from the wars , poverty , et.c , they never neglect their wood and used what they could find .

Keep woodworking and your happiness will be certain and long lasting .