The deep love for wood to enter to the wood “planet” is necessary , but the woodworking tools , are necessary also . I suppose even in the ancient times , the “first” human , needed some kind of a tool to cut and shape his trees .

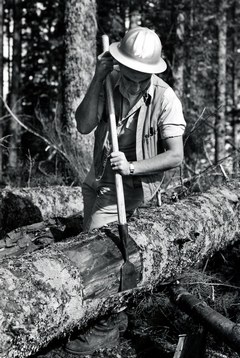

So after the appropriate advices and licence from your forestry agency , the attention to your safety , you have picked your wood piece and you are ready to cut it .

No matter how much money you can give to have a complete series of wood tools , you can have the basics with almost “pennies .

Some hand saws , some metric tools , some hammers ( wooden – iron – rubber ) , some screw drivers , a level tool , some pliers , some planners , some wood pencils , are some of the basic tools , you can have very easily .

Anyway , i think that having some of the primary tools to assist your wood “thirst” is something you can deal with , using your instant inventiveness .

How do you maintain woodworking tools ?

Avoid to hit their parts( metalic & wooden ) badly , use them according to their specification limits and never overdo it , avoid the moisture and wet conditions for a long time , clean them after the use , check for damages , fix them and lubricate them constantly with oils , waxes and grease .

If you want to storage them for a long time use fully synthetic grease , to avoid the hardening – become rancid , of it .

What are the 3 most Important Rules for too maintenance ?

1) Use the appropriate tool for the specific job .

2) Follow only the manufacturers advices for correct use and maintenance .

3) Storage them correctly away from dangers ( moisture – acids – weather changes ) , always having good air circulation away of moisture contacts and always make frequent checks for their general conditions and act fast to fix any issue .

How do you properly Clean and Lubricate woodworking tools ?

Right after the use , clean them with water and if needed with specialized cleaners ( for acids , chemicals , etc ) , inspect for damages or rust and fix them if needed and only when there are totally and completely dry use the appropriate oils , waxes and grease to lubricate them .

If there aren’t totally dry and you lubricate them you’ll “prison” moisture inside and the rust is certain .

What is the best Oil , for woodworking tools ?

Any natural – semi synthetic or totally synthetic oil can be used for the woodworkingtools lubrication , but you should be very cautious if you have a very special steel alloy , in which case you’ll need to get information from the manufacturer manual , to use the appropriate .

The best and elite rifle – shotgun manufacturers , the Japanese knife and sword makers , et.c , they use fully synthetic oils made for their steels , several natural and synthetic oils , camelia oil , very thin mineral oil and medical clean – pure mineral oil , in many cases .

The German Ballistol comes from the 1904 , it’s very safe for many uses and it’s an amazing oil used to clean even animal and pets skin !!!! Its’ very safe and a top class oil in my opinion .

Can Baby Oil , be used in woodworking ?

Yes , it can be used because it’s very elegαnt and safe for the babies skin and care , but of course you should be aware if your tool’s metalic parts have some special needs you need to follow from the official maker , the manufacturer .

Concerning the wooden parts of your woodworking tools , you won’t have any issue you can use baby oil for protection , even if it’s not the best solution you can have , but it’s fine for a short period of time .

Can i use Olive Oil , to lubricate woodworking tools ?

Yes , you can use olive oil for woodworking tools lubrication if you don’t have something more targeted and specialized for metalic and wood protection . It won’t hurt your steel or your wooden tool parts .

Is Coconut Oil , good for woodworking tools ?

The coconut oil which is a kitchen – cooking oil is a very fine lubrication solution for your tools if you haven’t something more special , because it has big amount of saturated fats that oxidize and gets rancid very slowly therefore it protects from moisture very effectively .

What is the best Lubricant for woodworking tools ?

The WD-40 or a fully synthetic oil which gets rancid very slowly along with a very good fully synthetic grease( which also gets rancid very slowly ) are top for the metalic parts and a nice 100% natural oil for the handles you touch with your hand’s skin , as the teak oil and the linseed oil , will be fine .

Does WD-40 clean tools ?

Yes , the WD-40 is a very capable element – lubricant – material , with “million” of uses and of course it can clean , recover , maintain , protect the metalic parts of your tools , but not for the wooden parts ( it may damage them ) with very high safety and effectiveness .

Many rifle – shotgun specialists are cleaning and protecting their shotgun barrels and metalic parts with WD-40 and they highly suggest it as a very capable product .

Remember , it’s not good for the wooden parts , it can damage their finishing and react badly with paints , stain , et.c . Avoid it .

I personally use the Ballistol i mentioned rpeviously for all the parts of my tools . It’s amazing and harmless for metal , wood , leather , et.c .

I don’t have a link to provide , but i think that their global site is ” www.ballistol.de ” , there is a 1904 German top company . I highly suggest you to make a check .

Can WD-40 , remove rust ?

Yes it can remove rust very effectively but you should have in mind that all the products that can remove rust , they can do in a very small level and if the rust is really deep , you cannot do anything because the metal has been “eaten” irreparably .

What is the Fastest way to remove Rust from woodworking tools ?

The very quick identification of rust and the treatment with a rust remover from the markets , the WD-40 , the Coca – Cola drink or white vinegar with some baking soda and salt or the light use of your abrasives ( sandpaper , steel wool , abrasive wheels , ) along with some oil for the rubbing process , will save the situation .

The WD-40 is very effective . It penetrates deep and it’s amazing good .

In the countless youtube restoration videos , you’ll see that the professionals remove rust with white vinegar mostly , electrolysis and sandblasting , but these are more expensive and special methods .

What Chemical breaks down rust ?

The white vinegar acids , the baking soda , lemon acids combined with salt , the WD-40 chemical formula are very effective to remove rust .

How do you prevent Rust , after cleaning the carpentry tools ?

If you don’t want to use a wide range of coating elements you can find in the stores or the expensive electrolytic paints and stuff like that , you should always keep the metalic parts of your tools with a thin layer of oil or grease or wax above them , to block moisture .

Does Vinegar get rid off rust of , from woodworking tools ?

Yes , the acid it cotains are very effective to the rust and of course we talk for the white vinegar which is the most effective that the red one .

Does Coca-Cola , remove rust from woodworking tools ?

Yes , you can use Coca-Cola but you may have to let the rusty part a little more inside Coca-Cola and if you combine it with white vinegar or WD-40 , even better .

What is the Difference between Surface rust and Deep rust ?

The light rusty surface is very easy to be fixed even from an amateur woodworker with some WD-40 or whatever , while the deep one which has damaged steel very deeply will need rectify by machines and professionals , to be cured .

The deep rust creates craters into metal and inside these craters moisture exist , “eating” metal slowly and steady with electrolytic procedures , no matter if you have lubricated the surface and you may feel that it’s ok .

The rust is working underneath eating metalic “flesh” , till the total destruction of the metal .

How do you take care , of wooden Handle tools ?

The wooden handles of the woodworking tools , come into constant contact with your skin and it’s recommended to use a 100% total natural element as oils , waxes , shellac , beeswax and the combination of them for protection and maintenance , with linseed oil and beeswax as some of the best on the list .

What is the best Oil for wooden Handles ?

The linseed oil , the teak oil in order to have a bug-fungi extra protection , the coconut oil with the slow rancid times are some of the most common and popular oils for wooden handles maintenance .

How do you maintain equipment in the workshop ?

Right after the correct use , cleaning and lubricating of your woodworking tools , you should storage the ones which have sensitive and sharp edges( handsaw , chisels , carving knives , etc) always alone , far from each other to avoid hits and damages (not inside cases moisture can penetrate ) and generally all your tools should have good air circulation and very few moisture around them .

The correct storage for the rifles and shotguns ( which have metalic and wooden parts too ) , is inside their show cases , well lubricated , with air circulation around them and never placed in their luxury cases made from velvet et.c .

The part which will be in contact with the fabric will develop rust after a while , caused from the contact and the air moisture .

I think the museums are using this storage maintenance mentality and approach .

Maintenance tips , for the wooden and metalic parts :(extended)

1) The Wooden parts maintenance .

There are many different ways to protect your wood from its “enemies” and the external conditions . Of course for the wooden parts of your wood tools you don’t need to use the Shou Sugi Ban method and burn your wood .

You don’t need also to use the impregnation method , which suits your wooden projects or use tar , grease , cuprum , or any other sophisticated chemical solution .

The wooden parts of the wood tools you can buy outhere , or you already have , are manufactured from the tool factories , to be strong and “tolerant” to many dangers . They are very good planed , to be smooth for your hands and they are covered with a thin layer of polish .

They are very pleasant in the touch , without any dangerous edges which could harm your hands . The “old days” some of them didn’t have any protection on them and the wood pores were free from any kind of polish .

Many times they used wax to cover the wood and that is a very hard “job” . You must have , a very good type of wax and the best wax for all purposes is the bees wax . The pure bee wax , without anything else inside .

But you didn’t have difficulties to find bee wax only . You needed to make it liquid , to cover the wood with a brush . Another serious theme was , that the wax was covered only the outside of the wood surface and didn’t penetrate the wood’s pores .

That’s why they rubbed the wax very strongly , in order to warm it so it can penetrate the wood deeply . Tough “job” and the effectiveness is at stake .

Nowdays a very good finishing oil can do way better “job” , by having the ability to go deeper inside the wood . Up to its “heart” and protect it entirely .

Another benefit of the wooden oil against the wax is that in a wax surface , any touch leaves marks with the water being its worse “enemy” .

So is you have a good wood oil and a cloth you can cover the wooden parts of your tools , let the surface “suck” the protecting oil physically and your “job” is done .

You don’t need something else and this process isn’t a process you need to do , very often . According to the use you make to your tools , you adjust this oil protection method .

I suppose 2 or 3 times per year is ok , depending the country you are , the specific weather conditions and the use you do .

If you want to be more “strict” and you want to combine the finishing oil and a very nice wax to “seal” the wooden surface , you can do that , it’s not “restricted” .

Oil your wooden surface , let it dry naturally and then you can wax it , to “seal” the whole process and make the wood more protected and waterproof .

I ‘ve picked some top oil and waxes product suggestions for you , in HERE .

Here i should say that if the wooden surface has marks on it from the use in the forest and wherever else , or cuts , gaps , scars , et.c , you should try to fix them .

Some of these marks can be fixed with a light rubbing with a sand paper , or by using with caution a little wood putty .

You shouldn’t let these marks “open” and unfixed , because from there the wood is vulnerable to moisture , water , et.c . They are “open wounds” for the wood .

I have some best grain fillers and other products for the job , in HERE .

In Greece when they prune the olive trees , or any tree and the tree owner wants to help the “healing” of the tree( because the “wound” is big) , they cover the tree “wound” from the prune with cuprum .

Cuprum works as the “medical iodium” for the open tree big “wound” and protects it from infections . So if your wooden tool handles have these kind of “wounds” , you should fix them .

As a conclusion , for the wooden parts for your wooden part of your tools , the covering with a good’s quality’s oil , is all you need to do .

Be flexible concerning the frequency of the oil coverings and you’ll face , no problems . If they have any marks , hits , or marks , fix them rubbing them or using some wood putty .

2) The Maintenance of the metalic parts .

The number one “enemy” for metal , in the outside world is rust . And rust is made from water and moisture in general . Not only from moisture of course , but water is the number one “enemy” . Other nature – forest fluids can cause rust for the metalic parts .

So after and every single time you use a wood tool and this use includes fluids , you must wipe the metal part and don’t let the fluids “work” on them for a long time .

So after the wiping of the metal parts the minute you return home , you should “run” and cover the metals with an anti rust oil , before you’ll storage them in their boxes .

If you don’t have anti rust oil , use whatever “oilish” you can find , but be careful this oil to be suitable for metals .

This is important and you should do it , every time in which your tools are getting “messy” with water , fluids , et.c . In this way you’ll retain your metalic parts in the closest position , as they were when you bought them .

But what happens when the metalic parts have “tons” of rust from the beginning because you didn’t take them fresh new , but from an old warehouse somewhere in a “forgoten” village house ?

What should you do fisrt of all ?

Removing the rust completely by rubbing the metal surface , no matter how many hours you’ll spend . You cannot do anything else before you remove entirely the rust from the tool . Rub it and rub it and rub it , till the metal be 100% clean .

After some relaxation and the satisfaction that you did the hard part of your metal part maintenance , return and cover the metal part with an oil substance .

In here again , if the metail part has gaps on it , “scars” , puddles and stuff like that , you need to clear them very carefully from rust , because rust “loves” these spots .

If you need to use any iron putty to “close” these gaps ? I don’t think so . Small or bigger puddles are common when we’re talking for woodworking tools , from the hits . The one you should always be cautious for it , is rust .

The sandpaper and the rubbing is the solution . If you intend to storage your tools for a long time , covering them with an oil factor . This will protect them efficiently and take a look at them , at a time to time .

Some of the best sandpapers and abrasives for you to supply , in HERE .

Protect your tools and they’ll Serve you for Years .

Nothing is “immortal” in life and your tools need some kind of protection , from you in order to use them for many , many years . And you don’t want to protect them to last in time only , but to serve you in the maximum grade .

What is the purpose to have a hand saw with great wood “waters” , wood condition and without any rust for its metal part , if it doesn’t have the ability to cut ?

What is the purpose to have a good and with zero rust hammer , if its hitting surface isn’t completely , straight so you can hit the pin with accuracy ?

What is the purpose to have the best plier , if it cannot catch and hold stable anything , because it has very big tolerances between its metal parts ?

So as you can see the correct and “wise” protection of your woodworking tools is something beyond the typical storage in a wood box , or something like that .

Your tools should be protected , while you use them , while you use them hard , while you use them continuously hard , while you use them daily , when you use them above their limits sometimes( this should be avoided of course ) , when you storage them for some days and when you storage them for longer time .

I’ve written a post for this , remember it in HERE .

The tools i have and their material are from plastic as some of the metric tools , i don’t do something specific for them . Plastic is material which doesn’t need anything for protection .

The external weather and other conditions of nature , have no affect in the plastic “life” . I suppose you know that if you bury a plastic bag to the ground , let it for 100 years and then you dig it up , it will be the exact same with no damage at all .

If you want to be 100% meticulous and you want to use something to protect the plastic and rubber parts , you can use glycerin .

Glycerin has the very interesting property to attract moisture , so for the rubber and plastic parts this is good , because they use moisture as a “food” to keep them fresh and flexible .

Your woodworking tools are manufactured mostly from wood and metal parts and in some cases , you can see a metal hammer with a plastic or rubber handle .

Summary :

1) In order to keep your woodworking tools in best “shape” , a good penetrating protecting oil for the wooden parts will be enough . A little wood putty will fix the puddles and gaps and then you can storage them in their box .

2) Removing entirely the rust of the metalic parts and then covering them with an oil factor will keep the metalic parts of the tools .

Be very carefull to remove the rust from the tiny “scars” and cuts in the metal , caused by the hits . Cover them with oil and storage them , as far from moisture you can .

A very Serious Tip coming from the “old school” carpenters .

After the continuous use of an ax to cut something , or a hammer with wooden handle or whatever woodworking tool ( this applies in general) , the connection between the wooden part and the metal part , starts to be loosen than its primary tightness .

This makes the metal part being unstable , as it used to be when it was brand new . To solve this problem , people used to put the tool inside a pot with water , in order to “suck” the wooden part water , become “thicker” and the tool being stable .

Of course this works . The wood absorbs water and the metalic connection part becomes stable . But , be carefull : only for a little while . When the wood dries , its diameter is returning to the previous state and the problem , still exists .

Of course the water “absorbing thing” , was repeated as many times you wanted to use the tool . But this process makes the wood to rotten . When you’ll grab the tool in your hand it’ll break to the connection with the metal spot .

If you are lucky , the free metal part won’t hit and hurt you . So try to avoid the water “sucking” process . Try to stabilize the tool , by using a screw , a pin , a wedge or something which can make the wood-metal connection , steady .

Try to wedge this pin or screw , between the connection and secure it , as better as you can . This is far better , lasts for years if you do it with great accuracy and it doesn’t affect the “life” of the wooden part .

You can also use also , melted silicone of you have a heat silicone pistol , to secure your wedge – pin , in the wooden part .

I think if you combine all these ( wedge – nail – silicone ) , you’ll make a very strong and steady wood – metal connection for your wood tools .

Work with wood , protect your woodworking tools , create your wood projects of your dreams and “allow” wood to give you happiness .