The order i should buy my first woodworking tools is a major woodworking question , especially when you start your woodworking “journey” and you’re kind of confused .

The order to purchase your first carpentry tools and the money issue , i suppose are some factors that any carpenter outhere , has faced in his life .

If you are a more experienced woodworker , once you were a complete amateur . Looking back , you may remember some mistakes you may did , with your woodworking tools purchase .

Of course i should remind you , that whatever woodworking tool you’ll buy in the future , it’ll need constantly maintenance and protection .

You should avoid the purchase of a tool , use it in your woodworking projects and then leave it , in its “luck” . All the materials in life gets old , have wear issues during time and they need maintenance .

The buying order of your woodworking tools , is totally attached to your first woodworking project and in general what kind of woodworking projects you’ll create the mostly starting from the basic first ones and escalate to the more difficult woodcrafts .

What Power tools , should i buy first ?

The amateur woodworker should start with a screwgun for his joinery , a power drill , an orbital sander and a miter saw to work it very carefully and learn and the more advanced should start with a table saw , a circular saw to be portable , a jigsaw , a planer and a power jointer to square boards and some power sanders .

What to buy first , a Planer or a Jointer ?

You should buy first the planer to learn to flatten wooden boards and get familiar to all this and then escalate to the more advanced jobs to square wooden boards , starting with your power jointer and proceed to the thickness planer .

Which hand plane , to buy first ?

You should start with a block plane which is a small to medium size plane , having the blade in a very low angle and it’s used to cut end grain easily and smoothly and it can be used with less power and with one hand many times .

Should i buy a Circular saw or a Jigsaw ?

If you’re a total beginner you should buy a jigsaw , which is way more easy to handle than the powerful circular saw and if you’re more experienced the circular saw should be your first purchase , in order to make a vatiety of cutting and be portable .

Should a Beginner use a circular saw ?

No , the total beginner shouldn’t start using a circular saw because it’s powerful enough , it hasn’t a steady basis as the arm type miter saw , it requires some strength to control it , it needs time and someone to show you and if you get a kickback from any reason , you’ll maybe get injured seriously .

The Order of your woodworking tools from total A to more Z is 🙁 extended )

1) Hand saw – axes – wedges , et.c .

Your hand saws and some green woodworking tools( hatchets , axes , a froe mallet , wedges , adzes , ) , in your cutting area , are basic columns for your woodworking starting .

If you cannot have all these and you can have only a couple , have an axe , a hatchet , maybe a splitting wedge(very cheap) , a couple of hand saws and a miter box , for precise angle cuttings.

You cannot cut – seperate wood primary , from the tree if you don’t have some axes , a hatchet to “clean it” from the branches , some bigger hand saws for the logs cutting( and later the smaller ones ) , some wedges , a maul and a splitting froe maybe , for splitting these logs .

Some of the the best axes in the markets for your tree cuttings , in HERE .

It isn’t necessary to have a chainsaw to cut entirely your tree trunk , if you cannot afford it . You can cut a big enough tree trunk with a nice and capable hand saw( a little bigger of course ) with a couple of breaks , to “catch your breath” .

If you can have a chainsaw , it’s welcomed of course , but if you cannot , no worries . The “job”can be done with a hand saw .

See some top panel saw – backsaw & more suggestions in HERE .

2) The table saw , if you want only one power tool in the cutting area .

I know that many cannot have a table saw , but if you can , the absolute “King” for your cuttings using power tools if you can afford its purchase , is the table saw and its so many uses it can give to you , no matter your level of experience .

Combining with your hand saws , you can cut whatever you like and if you cannot have any other power cutting tool , the table saw will give you the “freedom” to accomplish , many tough cuttings .

See some of my top table saw suggestions for you in HERE .

The circular saws , the miter saws , bandsaws and cutting power tools like , will come later when you’ll be more ready for them .

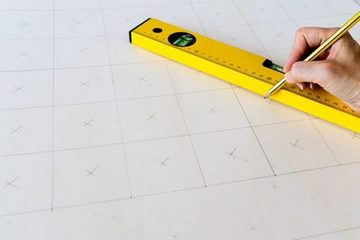

3) Measuring Tools .

Some rulers , tape meters some flexible and some not , some dividers , squares , are “must” in here in order to measure correct your wooden designs and proceed successfully to your marking , cutting , et.c , of your wood pieces .

The level tool should be in your tool “armory” , in order to measure straightness , in specific area and holistically .

See some basic rulers & more measuring equipment for buying in HERE .

4) Marking tools .

Some carpenter pencils , lead holders , some marking knives in order to mark your wood lengths and distances , that you have taken in the previous step , are needed and they’re very important .

Good measuring and accurate marking will lead to accurate and correct cutting of your wood . If you do any mistake in here and cut awry , there is no way to fix it .

See some pencil and lead holders to buy , in HERE .

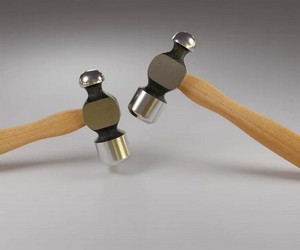

5) Hammer & mallets .

The hammers made from metal and the mallets which are made from soft materials( silicone , rubber , et.c ) , are surely necessary for any kind of woodworking project .

The soft mallets use is very important , to adjust , re-adjust and general fix wood parts with your small hittings of your plan , in order to make it perfect .

How can you use your nice antique nails for your connections , without a metalic hammer ? You cannot .

How can you micro – adjust your planes after the sharpening , without some small hammers for the job ? You cannot .

Metalic hammers of several sizes ( a claw to extract pins ) , are extremely helpful hand tools .

Try to have a two silicone mallets , one black and one from white silicone . You eliminate the posibility to have black spots from a hit to your wooden surfaces , et.c , using the white silicone mallet .

6) Chisels .

The chisels is another serious “chapter” for a woodworker and for sure a nice set( paring , corner , et.c ) of them , will give you the slicing – shaping wood details on your wood plans , making them perfect .

We use chisels in a variety of wood shaping from joinery , to slicing small or bigger wood parts for general design shaping and not only and the list is endless .

If you use a chisel correct you can slice wood fibers extremely accurate and shape wood very nice .

Have if you can afford some chisels with wooden handles and some with plastic ones for your harder hammer – mallet hits.

I’ve picked some very nice chisel suggestions for you to purchase , in HERE .

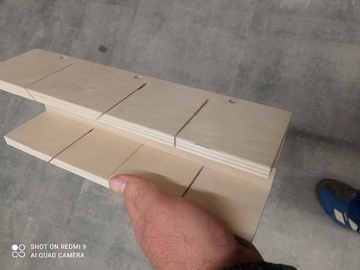

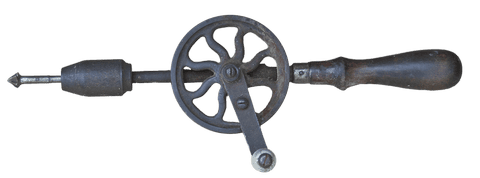

7) Drill , Brace and Bits .

Drilling wood is another basic “job” for a woodworker . You may want to drill wood to make holes and shape them to “eat” wood for a specific design , or to make pre-holes for your screws and whatever else .

For sure you’ll need to have some hand drills , a brace and a nice bits set for your first steps .

Later a T – handle augers for your green wood maybe , a power drill press later and a hollow chisel mortiser or a power router , when you’ll become more experience and have some money more to spend .

See some nice and reasonable priced drill presses to buy , in HERE .

8) Hand planes .

How can you be a woodworker without having some very nice hand planes to smoothen your wooden surfaces and finish – treat wood , to make it perfect .

You know if your hand plane is good and the blade is in “top shape” you can have smoothen results , which maybe won’t need even sanding from you .

See some of my top planes suggestions i have for you , in HERE .

9) Hand tools for curved wood shaping . ( spokeshaves , drawknives , et.c . )

Slicing wooden surfaces and parts in curved designs and pattern is something you’ll “confront” in woodworking and have some very good quality spokeshaves , some drawknives , will give you this ability .

See some spokeshaves , i’ve picked for you to buy , in HERE .

Of course these tools ave very capable for flat surfaces also and having some good sets of them will make you slice – shape – treat wood in all the possible design varieties with no limitation .

Even if these hand tools seem to be a little difficult , there aren’t and after a while working with them , you’ll be quit capable .

See my top drawknife suggestions from the markets , in HERE .

10) Carving Tools .

Carving gouges and carving knives , are some hand tools for your detailed wood carving , you should have in your carpenter’s toolbox , in order to carve wood detailed and hugely precise .

I’ve chosen some nice carving gouges from the markets , see some in HERE .

In many wooden plans you’ll need to carve – slice – trim wood in a very small scale and the gouges and carving knives are the appropriate tools for the job .

Maybe to fix a small error , or make a tough design , or adjust a surface for joinery , or whatever else , for sure these tools are welcomed and very helpful .

See some of my carving knives suggestions in order to do the above , in HERE .

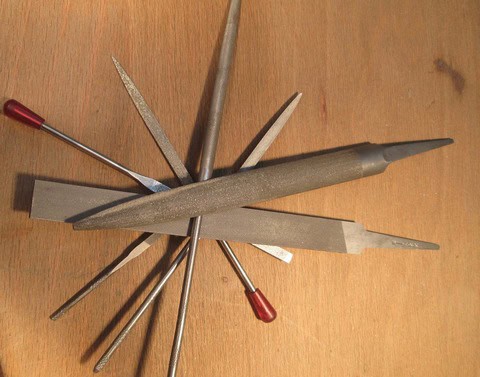

11) Sharpening Tools .

You hand tools for shaping – slicing – trimming – cutting tools , will need sharpening and the quality and precision of these processes , is very crucial for their longevity .

The several types of steel alloys of your hand tools will need very careful sharpening , bevel shaping , et.c , in order to make your carpentry jobs , in the highest possible level and avoid , mistakes that will cost you .

Sharpening stones ( water – oil – diamond) and a diamond plate to flatten your stones , sandpapers and a polishing strip , will be just fine for your beginning .

Later you can proceed and buy some water sharpening – grinding wheels , a bench grinder , et.c .

The full detailed post for the tools sharpening for you , in HERE .

12) Clamps , Glue – fasteners .

Some very serious assistants for you and your woodworking plans , are the several type of clamps , the wood glue , the nails , the screws and for sure , there aren’t “secondary” auxiliary tools .

Using some of the above and the many combinations you can make with them , you can hold your wood plans together for a while to do a parallel job , or you can hold them – join them together for ever .

See in HERE , my entire clarifying post for the wood fasteners .

You’ll need many types and sizes from the above wood helpers , no matter if you’re a totally amateur or you’re a totally professional carpenter .

Haven’t you see some very nice and expensive antiques , with antique nails on them for joining , et.c ? These elite wooden antique furniture is made from professional cabinet makers , who are using antique nails , screw , et.c for beauty reasons and not only .

13) Wood turning and Lathe Tools .

The wood turning and the lathe , are for more advanced woodworkers even if the wood turning isn’t so tough , as it seems .

Using a lathe , you can modify a wooden piece and give ot it a cylindical – symmetrical , shape and more .

If you cannot have a lathe it’s ok , you can supply one , later , when you’ll be more ready for it , but for sure the turning tools are serious helpers for the carpenter .

I’ve picked some lathe choices for your buying options , in HERE .

14) Winding sticks – Straightedges .

Between your woodworking steps and levels of work and certainly before your sanding and finishing , you’ll need to check your entire project for the correct flatness , for twistings , awry areas and the general icon of your wood plan .

Your plan should be perfect and straight in all of its dimensions and in the 3D scale .

If you find something that’s needs correctiosn , you should do it , before your sanding and finishing steps , using your planes , a straightedge and your winding sticks .

If you want to get some of my favorite winding sticks and straightedges , go in HERE .

15) Sanding tools .

After your all the previous woodworking actions using not all , but the exact appropriate wood tools , you’ll reach the point of sanding of your project , in order to finish it .

As your first steps , you don’t need to have an orbital sander , belts , et.c. and other power and more expensive tools . These power tools , you can buy – supply them , later .

You can do the sanding job , with raps , files , scrapepr cards , sandpapers and other abrasives .

For your primary more rough wood shaping – prepare for sanding tools , the raps are very nice hand tools and i’ve picked some very classical items for you to supply in HERE .

After the rasp – job of you , some nice and sharp files can shape wood more elite and detailed , using some files from you in order to proceed to your scaper cards , the sandpapers ,et.c .

I have some good bying file suggestions for your wood smoothing , in HERE .

Finallly the sandpapers , the other abrasives , the scraper cards are the last sanding actions from you before the finishing of your wood plan .

Some of the best sandpapers , abrasives , scraper cards in the markets are in HERE .

That’s it , you’re ready to go to your wood finishing and finish – protect your beloved plan .

16) Finishing tools – products .

That’s it , you ready to finish , protect your wood project and enjoy it for many years and decades . You can use a wide range of finishing – protecting gear , according to your needs and “apetite” .

For sure you’ll need some wood fillers , before your finishing and some of the best to buy , are HERE .

After your grain fillers , the wax sticks , et.c , you’ll need to choose between the many produsts , you want to use , to finish your wood .

My suggestion for your indoor wood plans , is to use products with the less possible chemicals , because you’ll breath them continuously .

I’ve picked some of the best natural finishing oils , waxes , shellac , et.c to buy , in HERE .

For your outdoor wood projects , you can use products with chemicals with more freedom , as oil based paints – water based paints – dyes , – lacquer , et.c.

I have some dyes – paint – varnishes , et.c . suggestions for you to supply in HERE .

17) Entire Range of Power Tools & accessories .

In this area , you can have and supply one , two , more , or all the entire range of the woodworking power tools , depending of the level of the professionalism you want to have .

If you want to be a totally professional carpenter , you should have , all the power tools and their accessories in my opinion . You should have the best possible quality of them , in order to have the fewer realibity problems and top quality , results .

I’ve written a post with all the power tool mentality , a totally professional carpenter should have in my opinion and you can read it in HERE .

If you aren’t a totally professional woodworker , you can begin having some power tools for starters and then proceed to more , during time .

Again in here , i suggest you to have the best possible power tools , you can . You’ll get the profit of this approach , over time .

18) Auxiliary tools .

The auxiliary tools and products , are needed from anyone who wants to act with woodworking , no matter if he’s an amateur or a professional .

Screwdrivers , tapes of several types , a small screw gun and a larger maybe , pliers , several types of solvents , many clothes and bandages for sweeping , plastic wires for temporary connecting and other auxiliary tools which you can find to every warehouse , are carpenter helpers , also .

19) Safety equipment – Dust collector .

If you’re an amateur woodworker , you may don’t want or need to have a dust collector and you don’t want to spend money to this .

If you cannot have a dust collector , you must have the best possible face mask and official air filters , you can buy , in order to protect your respiratory system and health .

Is woodworking toxic ? HERE is the answer .

You must have the best possible face mask , even if you have a dust collector . Never neglect you health safety measures .

Face mask , gloves , eyeglasses , ear protection and your 100% focus to your safety is a law .

See in HERE , my complete safety mentality for woodworking and why .

My first seat , was like this and i love it so much .

Your first wood plans will be simple and primary wood plans , so the order of your woodworking tools should be the same simple and primary . The order of your wood tools , should be based in the logic of your first wood projects you’ll make .

My personal woodworking tools purchases , followed the same approach and mentality .

Your first (and mine) wood creation won’t be i suppose a professional highly sculptured wooden library or a medieval type , wooden chair . Mine didn’t also .

Your first creations will be the basic and the “common” projects , we all have made in our beginning .

I leave it last but for sure not least . Never forget your safety measures and the safety equipment . Never forget that , yes in the woodworking activity – way of life , dangers exist and you need to get some necessary safety equipment .

Work with wood and “spoil” yourself with tons of happiness .